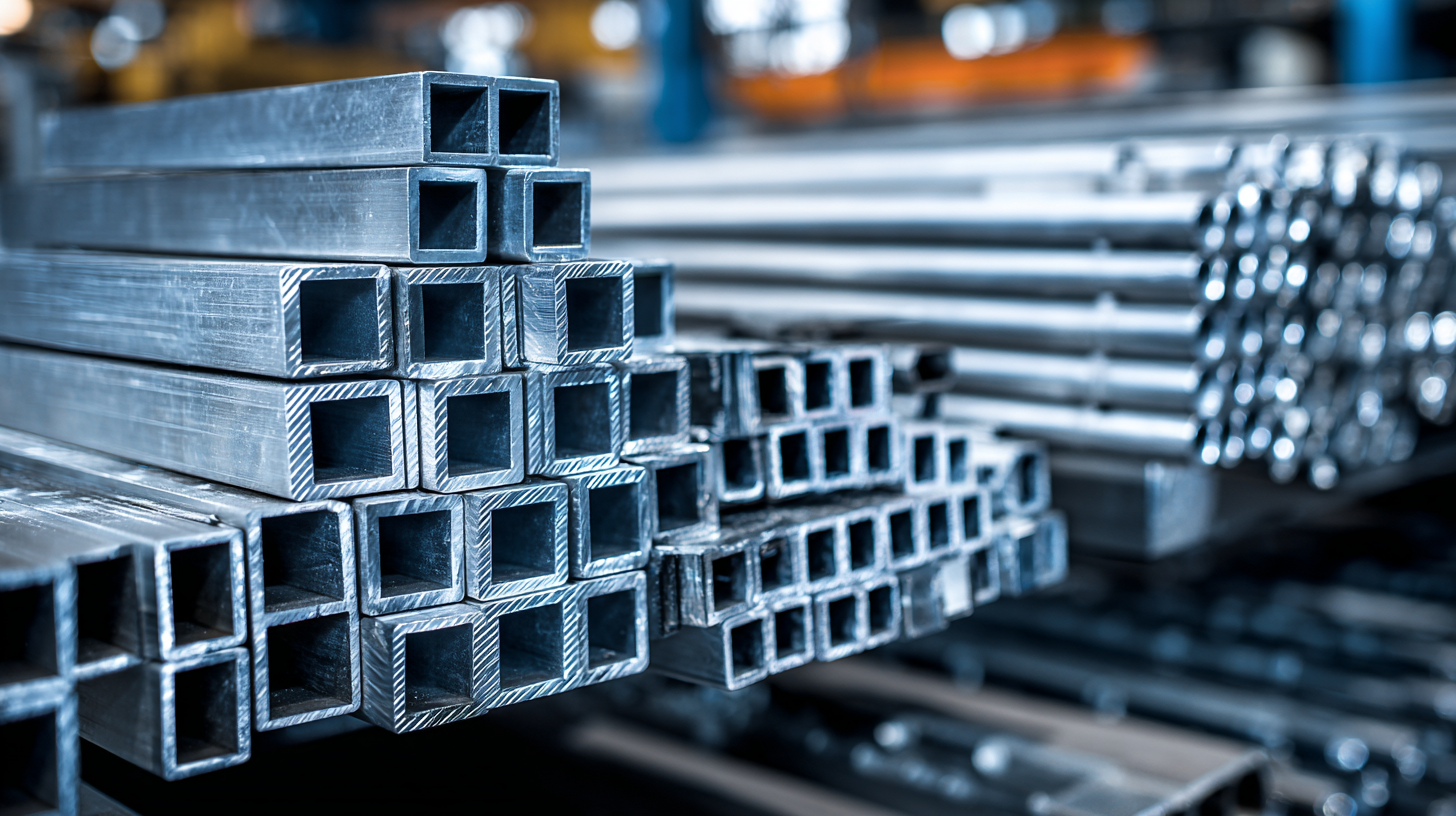

As we delve into the 2025 market trends and future prospects of aluminum extrusion, it’s essential to recognize the significant role this process plays in various industries. According to a recent report by ResearchAndMarkets, the global aluminum extrusion market is projected to reach USD 50 billion by 2025, with a compound annual growth rate (CAGR) of 5.2% from 2020 to 2025. This growth is driven primarily by the increasing demand from automotive, construction, and consumer goods sectors, all seeking lightweight yet durable materials. Moreover, advancements in manufacturing technologies and sustainable practices in aluminum production are likely to reshape the landscape, providing new opportunities for innovation. In this tutorial, we will explore these emerging trends, key drivers, and the future outlook of the aluminum extrusion industry, equipping you with insights to navigate this dynamic market effectively.

As we approach 2025, the aluminum extrusion market is set to witness significant transformations driven by emerging industries. One of the most promising sectors leveraging aluminum extrusion is the electric vehicle (EV) industry. According to a report by the International Aluminum Institute, the demand for aluminum in EVs is expected to increase by 30% annually through 2025, as manufacturers seek to reduce weight and enhance energy efficiency in vehicles. This trend is not only beneficial for manufacturers but is also pivotal in meeting the global push for sustainable transport solutions.

Another key player in this landscape is the construction industry, particularly in developing smart buildings and infrastructure. The latest insights from Smithers Pira indicate that the architectural sector’s use of aluminum extrusion will grow by 15% in the next two years, driven by the rise in demand for sustainable and energy-efficient building materials. The versatility of aluminum allows for innovative designs while maintaining structural integrity, making it a favored choice for architects and builders alike. As these industries evolve, the implications for aluminum extrusion manufacturers are profound, ushering in new opportunities for growth and technological advancements in production processes.

Aluminum extrusion is revolutionizing automotive design, offering lightweight yet durable components that enhance vehicle performance and efficiency. With growing demands for sustainability and fuel efficiency, manufacturers are increasingly turning to aluminum extrusion for its ability to create complex shapes and structures that can reduce overall vehicle weight. This shift not only optimizes energy consumption but also aligns with the industry's push toward greener technologies.

When exploring innovative applications, consider integrating aluminum extrusions in the chassis and structural components of vehicles. This reduces weight while maintaining structural integrity, enabling automakers to improve acceleration and braking. Moreover, the versatility of aluminum allows for sleek designs, making it easier to incorporate aerodynamic features that complement modern automotive aesthetics.

Tips for manufacturers looking to leverage aluminum extrusion in automotive design include investing in advanced extrusion technologies that enhance precision and surface finish. Collaborating with experienced suppliers can also help in developing tailored solutions that meet specific design requirements. Finally, staying updated on industry trends and material innovations will ensure your designs remain competitive and aligned with consumer preferences for sustainability and performance.

Aluminum extrusion has emerged as a pivotal element in the realm of sustainable construction practices. As the industry shifts toward greener solutions, aluminum’s unique properties—such as its lightweight nature, strength, and recyclability—make it an ideal choice for eco-friendly building designs. By utilizing aluminum extrusion, architects and builders can create innovative structures that reduce energy consumption and minimize waste. Its versatility allows for customizable profiles that can meet diverse aesthetic and functional requirements, making it an integral part of modern, sustainable architecture.

Furthermore, the circular economy concept is gaining traction in construction, and aluminum extrusion is at its heart. With the ability to be recycled indefinitely without loss of quality, aluminum supports sustainable resource management. Construction projects that incorporate extruded aluminum components can significantly decrease their carbon footprints while enhancing energy efficiency. As we move towards 2025, the emphasis on sustainable materials in construction is likely to increase, positioning aluminum extrusion as a key player in the drive for more environmentally responsible building practices.

The aluminum extrusion industry is witnessing transformative advancements that are shaping its future. With the growing demand for lightweight and durable materials across various sectors, technological innovations are becoming crucial. Modern extrusion processes are incorporating advanced robotics and automation, leading to enhanced precision and efficiency. These improvements not only increase production speed but also reduce waste, paving the way for sustainable manufacturing practices.

**Tip:** Consider investing in automation technologies. Upgrading your equipment and incorporating robotic systems can drastically improve your production capabilities and reduce labor costs in the long run.

Furthermore, innovations in alloy development are contributing to enhanced properties for extruded products. New alloy formulations are increasing strength, corrosion resistance, and thermal conductivity, making aluminum extrusions more versatile for applications in automotive, aerospace, and construction markets. Companies that stay ahead with R&D investments and adopt cutting-edge materials will position themselves favorably in a competitive landscape.

**Tip:** Keep a close eye on emerging materials and alloys. Engaging with suppliers and research institutions can give you insights into the latest trends and opportunities for product development.

Aluminum extrusion is gaining momentum across various sectors due to its lightweight, durability, and versatility. In the automotive industry, for example, companies like Tesla have successfully implemented aluminum extrusions in their vehicles to enhance performance while reducing weight. According to a report by the Aluminum Association, the automotive sector is projected to consume approximately 7.5 million tons of aluminum by 2025, with a significant portion attributed to extruded components that improve energy efficiency and range.

In the construction sector, aluminum extrusions are being utilized in architectural designs and structural components. A notable case is seen in the construction of high-rise buildings, where aluminum framing systems offer not only aesthetic appeal but also superior strength and resistance to corrosion. The Global Aluminum Extrusion Market report indicates that the building and construction segment accounted for more than 25% of the total extrusion market share in 2022. This figure highlights the growing preference for aluminum extrusions in sustainable building practices, as they contribute to energy efficiency and reduced environmental impact.

| Sector | Application | Benefits | Market Growth (%) | Future Prospects |

|---|---|---|---|---|

| Automotive | Lightweight structural components | Improved fuel efficiency and performance | 5.4% | Increasing demand for electric vehicles |

| Construction | Window frames and facades | Durability and aesthetics | 4.8% | Growing focus on green buildings |

| Aerospace | Aircraft frames and components | Weight reduction and fuel savings | 6.2% | Increase in commercial air travel |

| Electronics | Heat sinks and enclosures | Effective heat dissipation | 3.5% | Rising demand for consumer electronics |

| Packaging | Aluminum cans and containers | Recyclability and protection | 2.9% | Sustainability trends driving growth |