In the realm of modern construction and manufacturing, Aluminum Profiles have emerged as a pivotal component due to their lightweight, durability, and versatility. As industries worldwide continue to evolve, the demand for high-quality aluminum solutions has surged, necessitating a thorough understanding of the essential technical specifications and installation techniques associated with these profiles. This blog aims to guide readers through the intricacies of mastering Aluminum Profiles, highlighting their significance in various applications while also emphasizing the reliable craftsmanship that comes from "China manufacturing, global sharing, and trusted quality." By the end of this article, you will be equipped with the knowledge needed to effectively select, install, and utilize aluminum profiles, ensuring that your projects stand the test of time and performance.

Aluminum profiles are versatile elements widely used in various industries due to their lightweight properties, corrosion resistance, and excellent strength-to-weight ratio. Understanding the different categories of aluminum profiles, such as structural, architectural, and decorative profiles, is essential for selecting the appropriate type for specific applications. According to a recent market report by Mordor Intelligence, the global aluminum profile market is expected to reach $58 billion by 2026, primarily driven by increased demand in construction and automotive sectors.

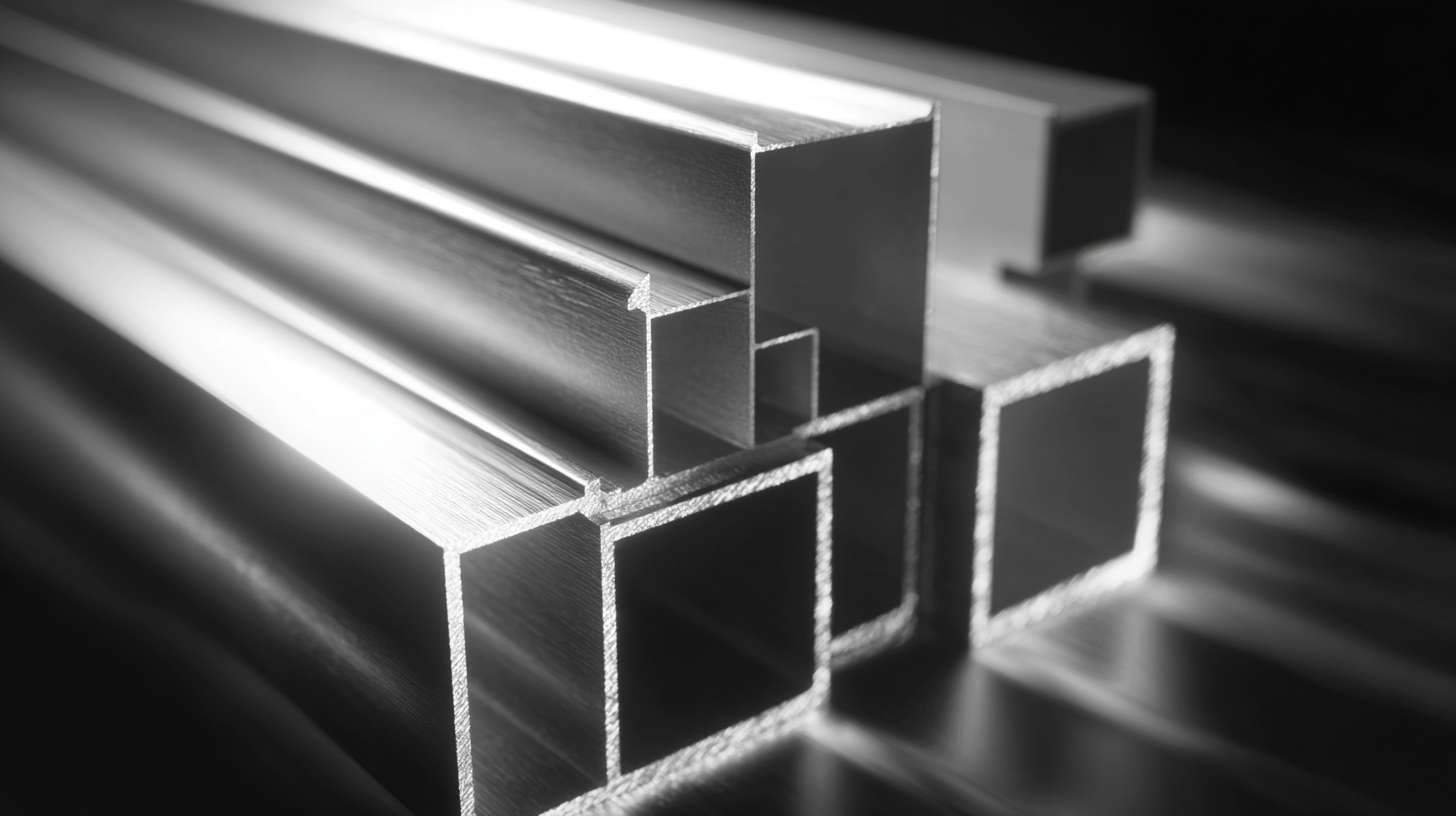

Structural profiles, often used in frames, supports, and rails, have dimensions and shapes designed to ensure maximum strength and durability. Architectural profiles, on the other hand, focus on aesthetics and are commonly utilized in window frames, doors, and curtain walls. Decorative profiles can be employed in signage and interior design, providing both functional support and visual appeal. When selecting an aluminum profile, consider the intended use, load requirements, and environmental factors that may affect performance.

Tips: Always consult with suppliers for the latest specifications and potential applications before making a purchase. Additionally, ensure proper installation by following guidelines specific to the category of aluminum profile you are using, as this can significantly affect the long-term performance and safety of the structure. Moreover, keep an eye on market trends for emerging applications that could influence your project outcomes.

When selecting quality aluminum profiles, understanding key technical specifications is essential to ensure you choose the right products for your project. First and foremost, consider the alloy type. Aluminum alloys vary in their strength, corrosion resistance, and workability. For instance, 6061 is a commonly used alloy due to its good mechanical properties and weldability, while 6063 is favored for architectural applications due to its excellent finish and formability. Evaluating the temper (or hardness) of the aluminum is equally important, as it impacts the durability and intended use of the profile.

Another critical specification is the thickness of the aluminum profile. Thicker profiles can support heavier loads and are more resistant to deformation and environmental stresses. Additionally, pay attention to the surface finish, such as anodizing or powder coating, which can enhance corrosion resistance and aesthetic appeal. Finally, ensure that the profiles meet relevant industry standards, which can provide assurance of their performance and reliability. By keeping these specifications in mind, you can make informed decisions when selecting the best aluminum profiles for your needs.

Installing aluminum profiles can be a straightforward yet technical process that requires attention to detail and a solid understanding of the material properties. According to a report by the Aluminum Association, aluminum's durability and resistance to corrosion make it a preferable choice for a variety of applications, especially in construction. In this guide, we will provide you with a step-by-step strategy to ensure that your installation is effective, maximizing the potential benefits of aluminum profiles.

First, it’s essential to prepare your materials and tools before beginning the installation. This includes measuring the area accurately, as industry standards suggest that an error margin of only 1-2% can impact the structural integrity significantly. Next, ensure you have the correct profile design, as using the right cross-section—typically made from alloys like 6061 or 6063—can enhance load-bearing capabilities as confirmed by a study from the American Society for Metals. Once your materials and tools are ready, follow the recommended anchoring techniques for securing profiles, which often utilize specific fasteners to withstand varying loads and prevent deformation. Proper installation not only extends the lifespan of the profiles but also enhances the efficiency of your overall project.

When working with aluminum profiles, avoiding common mistakes can significantly enhance your project’s quality and durability. One frequent error is neglecting to account for thermal expansion. Aluminum expands and contracts with temperature changes; thus, allowing adequate space for movement in your design is crucial. Failing to do so can lead to warped structures and compromised fittings, ultimately necessitating costly repairs.

Another common pitfall is improper handling during installation. Aluminum, while lightweight, is still susceptible to bending and scratching if not managed correctly. Always ensure profiles are properly supported during transport and assembly. Utilizing the right tools, such as clamps and supports, can prevent damage and improve the precision of your work. Additionally, overlooking the importance of correct fasteners can result in weak joints that may fail over time. Selecting the appropriate screws or bolts designed for aluminum is essential to ensure strong, reliable connections.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Common Uses | Installation Tips |

|---|---|---|---|---|

| Square Tube | 20 x 20 | 1.5 | Frameworks, Supports | Ensure square alignment during assembly. |

| Rectangular Tube | 30 x 15 | 2.1 | Structural Applications, Railing | Check for even surface before fixing. |

| Angle Profile | 25 x 25 | 1.2 | Bracing, Supports | Use proper fasteners to avoid stripping. |

| Channel Profile | 50 x 25 | 3.0 | Track Systems, Frameworks | Align correctly to avoid misalignment. |

The aluminum profile manufacturing industry is witnessing a transformative evolution driven by innovative technologies and emerging trends. As sustainability becomes a central theme in manufacturing, the focus on recycled aluminum is stronger than ever. Manufacturers are increasingly using recycled materials, which not only reduces waste but also lowers production costs and energy consumption. This shift not only helps the environment but also meets the growing consumer demand for sustainable products.

Another significant trend in aluminum profile manufacturing is the integration of smart technologies. Automation and Industry 4.0 are playing pivotal roles in enhancing production efficiency and precision. Advanced robotics and AI-driven systems facilitate real-time monitoring and quality control, minimizing human error and streamlining processes. Moreover, the adoption of 3D printing technology is revolutionizing design possibilities, allowing for more complex and customized aluminum profiles that cater to specific project needs. As these innovations continue to unfold, the future of aluminum profile manufacturing looks promising, paving the way for enhanced productivity and sustainability.