In the rapidly evolving landscape of manufacturing, the quest for quality and cost-effective sourcing has become increasingly vital, particularly in the aluminum extrusion sector. With China leading the global manufacturing arena, its industry insights and strategies have proven indispensable for businesses seeking reliable suppliers. As reported by the International Aluminum Institute, the demand for aluminum extrusion profiles, specifically Channel Aluminum Extrusion Profiles, is projected to grow by 4% annually, driven by their rising applications in construction, automotive, and aerospace industries. This growth underscores the importance of identifying and partnering with the best suppliers who not only offer competitive pricing but also adhere to stringent quality standards. By leveraging proven strategies and insights from experienced players in the field, businesses can enhance their procurement processes, ensuring they remain competitive in both domestic and international markets.

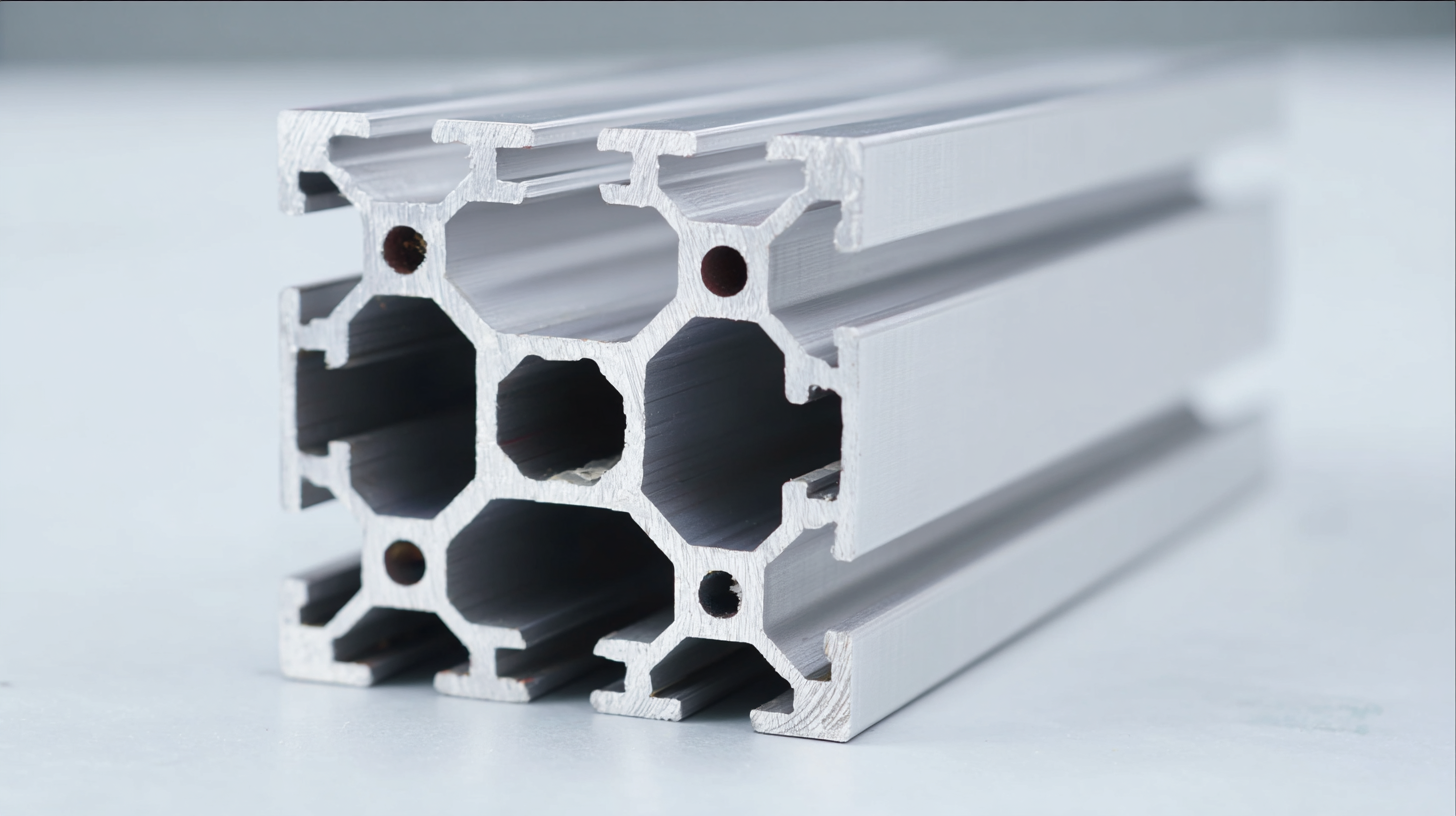

Quality control plays a crucial role in the aluminum extrusion supply chain, ensuring that products meet industry standards and customer expectations. In a market where precision and durability dictate the success of applications ranging from construction to automotive, maintaining strict quality standards is non-negotiable. Suppliers must implement robust quality control measures at every stage of the extrusion process. This includes meticulous inspections of raw materials, monitoring of extrusion temperatures, and continuous testing of finished profiles against predefined specifications.

Moreover, fostering strong relationships between suppliers and manufacturers can enhance quality control efforts. Open communication allows for quick identification of discrepancies and facilitates immediate corrective actions. By collaborating closely, both parties can share best practices and innovatively address quality challenges. Ultimately, investing in quality control not only minimizes defects but also boosts the overall efficiency of the supply chain, leading to enhanced customer satisfaction and loyalty in an increasingly competitive market.

In the evolving landscape of aluminum extrusion, businesses must navigate key industry trends that significantly influence supplier selection. One primary trend is the increasing demand for customized solutions to meet specific project requirements. Suppliers that can provide tailored designs, along with flexibility in production, are becoming essential. This shift towards customization requires suppliers to possess advanced technological capabilities and a responsive approach to client needs, ensuring they can accommodate varying specifications and timelines.

Another trend affecting supplier choice is the growing emphasis on sustainability and green practices. Companies are now more inclined to partner with suppliers who prioritize eco-friendly materials and processes. Suppliers that demonstrate a commitment to reducing carbon footprints, utilizing recyclable materials, and implementing sustainable manufacturing practices not only attract more clients but also foster stronger partnerships built on shared values. As industry stakeholders prioritize responsible sourcing, choosing suppliers with verifiable environmental credentials is increasingly becoming a non-negotiable criterion.

When evaluating supplier capabilities for aluminum extrusion profiles, several essential metrics emerge as critical indicators of performance and reliability. According to a report by the Aluminum Association, approximately 70% of aluminum manufacturers cite supplier reliability as a cornerstone for maintaining operational efficiency. This highlights the need for manufacturers to focus not only on price but also on the consistency and quality of service offered by suppliers. Key metrics include lead time, production capacity, and past project performance, which collectively contribute to a supplier's ability to meet the demands of fluctuating market conditions.

Another crucial metric is material traceability, important for ensuring compliance with industry standards and reducing liability risks. A survey conducted by Ernst & Young found that 65% of manufacturers prioritize suppliers who can verify their raw material sources, reflecting the growing emphasis on sustainability and ethical sourcing in the aluminum industry. By scrutinizing these metrics, manufacturers can better align with suppliers who not only deliver high-quality products but also strengthen their overall supply chain integrity and support long-term business partnerships.

| Supplier Location | Production Capacity (tons/month) | Quality Certifications | Lead Time (weeks) | Customer Satisfaction Rating |

|---|---|---|---|---|

| North America | 1500 | ISO 9001, AS 9100 | 4 | 92% |

| Europe | 1200 | ISO 14001, OHSAS 18001 | 6 | 89% |

| Asia | 2000 | ISO 9001, ISO 50001 | 3 | 95% |

| South America | 800 | ISO 9001 | 5 | 88% |

| Middle East | 900 | ISO 9001 | 7 | 85% |

The global aluminum extrusion market is booming, with certain countries standing out as leaders in production. China remains the largest producer, accounting for a significant share of the worldwide output. Its extensive manufacturing capacity allows for cost-effective production, making it an attractive option for businesses seeking aluminum extrusion profiles. Other noteworthy countries include the United States and Germany, known for their advanced technology and high-quality standards. These nations are crucial for companies looking to source specialized aluminum products.

When searching for the best suppliers in the aluminum extrusion sector, it's essential to consider a few key tips. First, evaluate their production capabilities and technology. Suppliers with modern extrusion machines are more likely to meet precise specifications and complex designs. Second, check for industry certifications that vouch for quality and compliance with international standards. This not only enhances trust but also ensures that the products you receive are reliable and durable. Finally, establishing strong communication with potential suppliers will help streamline the process and foster better collaboration for future projects.

In the quest for the best suppliers of aluminum extrusion profiles, choosing partners who prioritize sustainable practices is crucial. Companies today are increasingly aware of their environmental impact, making it essential to select suppliers who demonstrate a commitment to sustainability through their operations. When evaluating potential suppliers, key criteria should include their use of recycled materials, adherence to eco-friendly production processes, and implementation of energy-efficient technologies. Suppliers engaged in responsible sourcing and waste reduction initiatives not only contribute positively to the environment but also align with the growing consumer demand for sustainable products.

Moreover, suppliers that transparently share their sustainability practices can foster trust and long-term partnerships. Look for those who provide detailed information on their carbon footprint reduction efforts, compliance with environmental regulations, and certifications like ISO 14001. Engaging with suppliers who prioritize sustainability can also lead to innovative solutions in product design and manufacturing, enabling businesses to stay competitive in a rapidly changing market. By incorporating these supplier selection criteria, companies can effectively navigate the landscape of aluminum extrusion procurement while supporting a greener future.