As the global demand for lightweight and durable materials continues to rise, aluminum profiles have emerged as a pivotal component across various industries, particularly in construction and transportation. According to a report by the Aluminum Association, the global aluminum market is projected to reach 300 million metric tons by 2025, driven by the increasing need for energy-efficient solutions and sustainable materials. China's leading factories are at the forefront of this transformation, producing high-quality aluminum profiles that meet international standards. In the context of the "Industry 2025" technological trends, advancements such as automation and smart manufacturing are revolutionizing the production of aluminum profiles. This blog will explore how Chinese manufacturers are setting benchmarks in quality and innovation, making their products unmatched on a global scale.

When it comes to sourcing aluminum profiles, China’s leading factories offer unmatched quality that sets them apart in the global market. These manufacturers utilize advanced technology and state-of-the-art production techniques to ensure that every profile meets the highest standards. This commitment to excellence not only enhances the durability and performance of the products but also provides clients with a reliable supply chain capable of meeting large-scale demands.

Additionally, the advantages of sourcing aluminum profiles from China extend beyond quality. Competitive pricing is a significant benefit, as these factories operate with efficient processes that reduce production costs. Furthermore, China's robust logistics infrastructure allows for timely deliveries, ensuring that businesses can maintain their productivity without delays. The combination of superior craftsmanship, cost-effectiveness, and reliable service makes Chinese aluminum profiles an attractive choice for manufacturers and builders worldwide.

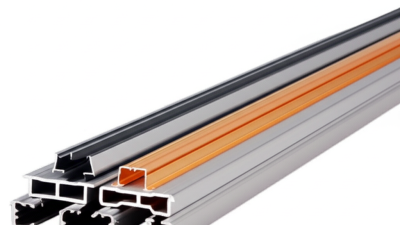

Aluminum production is undergoing a remarkable transformation driven by innovative manufacturing techniques, significantly enhancing quality and efficiency. Advances such as Shear-Assisted Processing and Extrusion (ShAPE) are reducing energy consumption and carbon emissions while improving the quality of raw materials. This method allows manufacturers to produce higher-grade aluminum profiles at lower costs, contributing to the global trend of sustainable manufacturing. Additionally, the integration of lightweight composite structures in aluminum fabrication technology is revolutionizing product applications, leading to enhanced performance and reduced material usage.

One notable innovation is the use of large-format additive manufacturing, which has been shown to increase productivity by streamlining the metal printing process. As the demand for customized and complex aluminum components rises, this technology enables manufacturers to meet diverse client needs efficiently and effectively. Reports indicate that companies adopting these advanced techniques are witnessing substantial improvements in production rates and product quality.

Tips: When exploring innovative techniques in aluminum production, consider incorporating sustainable practices into your strategy. This not only aligns with current industry trends but also improves your brand reputation. Stay updated on research and advancements to ensure your manufacturing processes remain competitive and efficient.

The aluminum profile industry is at a pivotal point, with sustainability becoming a core focus for leading manufacturers, particularly in China. A recent report by the International Aluminum Institute highlights that aluminum production contributes to about 1% of the global greenhouse gas emissions, prompting industry players to adopt innovative, eco-friendly practices. Chinese factories are now exploring low-carbon technologies and energy-efficient processes that can significantly reduce their carbon footprint. For instance, advancements in recycling technologies have made it possible to reuse up to 90% of the aluminum, thus minimizing waste and environmental impact.

Moreover, a study published by McKinsey & Company indicates that the demand for sustainable aluminum is increasing. Clients are now prioritizing suppliers who employ responsible sourcing and environmentally conscious operations. In response, many prominent Chinese manufacturers are investing in renewable energy sources for their production processes. The integration of solar and wind power not only enhances energy efficiency but also positions these companies as leaders in the global market, offering unmatched quality in aluminum profiles while adhering to sustainable practices. As the industry transitions toward a greener future, these initiatives set a benchmark for quality and environmental responsibility.

| Region | Production Volume (tons) | Sustainability Rating | Average Lead Time (weeks) | Recycling Rate (%) |

|---|---|---|---|---|

| China | 100000 | A+ | 4 | 90 |

| Europe | 50000 | A | 6 | 85 |

| North America | 30000 | B+ | 5 | 80 |

| Southeast Asia | 25000 | B | 7 | 75 |

| Latin America | 15000 | C+ | 8 | 70 |

High-quality aluminum profiles are transforming modern construction, providing lightweight yet durable solutions that are essential for various applications. According to the Aluminum Association, the demand for aluminum in building and construction is projected to reach over 12 million metric tons by 2025. These profiles are favored for their versatility, energy efficiency, and recyclability, making them a sustainable choice for architects and builders.

In buildings, aluminum profiles are used extensively in windows, doors, and curtain walls, contributing to both aesthetic appeal and functionality. A report by MarketsandMarkets indicates that the global market for aluminum structural products is expected to grow at a CAGR of 4.3% between 2020 and 2025. This growth is driven by the increasing need for energy-efficient structures and the use of lightweight materials that facilitate faster construction and reduce overall costs. Additionally, innovations in anodizing and powder coating techniques enhance the performance and longevity of aluminum profiles, making them an ideal solution in modern architectural design.

As the global demand for aluminum profiles surges, China has positioned itself not only as a leading manufacturer but also as a formidable competitor on the worldwide stage. A comparative analysis of Chinese aluminum profiles and those from other global manufacturers reveals that China's production capabilities are unmatched in terms of quality and affordability. With an estimated market growth of 6.9% CAGR from 2023 to 2030, the strategic significance of aluminum in industries such as electric vehicles amplifies this competitive edge.

However, challenges such as sustainability in the aluminum supply chain and the increasing need for decarbonization are reshaping industry dynamics. China's innovative approaches in the electric vehicle and battery sectors exemplify its commitment to sustainable practices, influencing the broader aluminum market. Companies operating within this sector must navigate unique challenges posed by evolving trade patterns and international competitive landscapes, underscoring the complexity of operating in a globalized economy where China's dominance doesn't just hinge on scale but also on technological advancement and sustainable practices.