When embarking on a project that requires Channel Aluminum Extrusion Profiles, the decision-making process can often feel overwhelming due to the variety of options available. Industry expert Dr. John Smith, a renowned authority in aluminum manufacturing, emphasizes the importance of understanding your specific requirements: "Choosing the right Channel Aluminum Extrusion Profiles can make or break the success of your project." This statement underlines the necessity for meticulous consideration when selecting profiles that best suit your application.

Channel Aluminum Extrusion Profiles serve a multitude of purposes in sectors ranging from construction to automotive. The versatility and lightweight nature of aluminum, combined with its strength, make it an ideal choice for structural support and aesthetic features alike. However, navigating the array of profiles, finishes, and sizes can be complex. It’s essential to evaluate factors such as load-bearing capacity, environmental conditions, and end-use to ensure optimal functionality.

By taking the time to research and consult with experts, project managers can enhance their understanding of Channel Aluminum Extrusion Profiles and make informed decisions. This initial investment in knowledge and resources will significantly contribute to the efficiency and longevity of the projects they undertake. Understanding these profiles is not just about choosing the right material; it's about creating a sustainable and functional design that meets project goals.

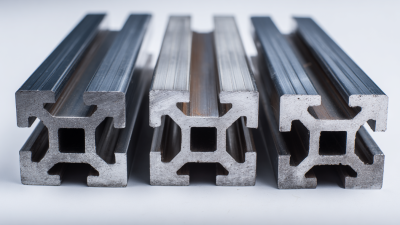

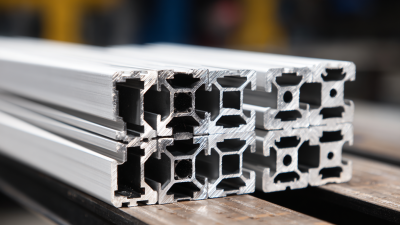

When working on a project that requires channel aluminum extrusion profiles, it’s crucial to understand their fundamental characteristics. Channel aluminum profiles are versatile components used in a variety of applications, from structural supports to decorative purposes. They typically have a U-shaped cross-section, which enhances their strength and stability while allowing for efficient integration into different designs. Familiarizing yourself with the dimensions and weight load capacities of these profiles can help you select the right type for your needs.

Tips: Always measure the specific requirements of your project before making a decision. Consider the maximum load that the profile must support, as this will influence the thickness and width of the channel needed. Additionally, take into account the environmental factors such as exposure to moisture or chemicals, as these can affect the performance and durability of the profiles over time.

Another essential factor to consider is the fabrication and finishing options available for channel aluminum extrusions. Depending on the project's aesthetic and functional requirements, you might want to explore various surface treatments such as anodizing or powder coating. These treatments not only enhance the appearance but also provide increased corrosion resistance, ensuring longevity.

Tips: If your project involves custom lengths or specific cuts, it may be worthwhile to discuss customization options with your supplier. This can help streamline your assembly process and reduce waste, ultimately leading to a more efficient workflow.

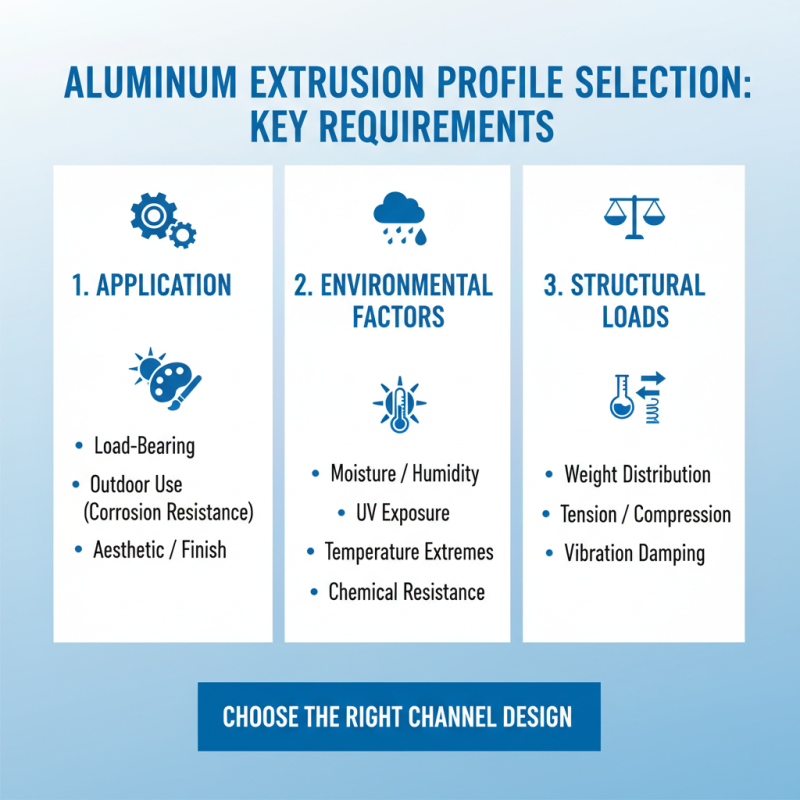

When embarking on a project involving aluminum extrusion profiles, identifying the key requirements is crucial for selecting the right channel design. First, consider the specific application of the profiles. Factors such as load-bearing capacity, environmental exposure, and the desired aesthetic can greatly influence your selections. For instance, profiles destined for outdoor use must be selected with corrosion resistance in mind, while those meant for structural applications need to accommodate specific weight and tension loads.

Another important consideration is the manufacturing process. Understanding whether your project requires custom profiles or can utilize standard shapes can streamline the selection process. Additionally, take into account the dimensions and tolerances needed for your project, as these will affect the performance and compatibility of the extrusion with other components. By carefully assessing these key requirements, you can make informed decisions that align with your project's goals and ensure the effectiveness of the aluminum extrusion profiles you choose.

When evaluating different types of channel aluminum extrusions for your project, it’s crucial to consider the specific requirements of your application. Channel aluminum extrusions come in various shapes and sizes, tailored for a range of uses from structural support to aesthetic design elements. Start by identifying the load-bearing capacity needed and whether the extrusion will face environmental factors such as moisture or temperature variations.

Tips: Always consult specifications to determine the strength and durability of different channel profiles. This ensures that the selected extrusion can withstand the mechanical stress it will encounter in your project, providing longevity and reliability.

Additionally, the finish of the aluminum can significantly impact both functionality and appearance. Anodized finishes offer enhanced corrosion resistance, making them suitable for outdoor applications, while powder coating provides a wide range of color options for visual appeal. Make sure to assess how the finish aligns with the intended use and design aesthetic of your project.

Tips: When selecting finishes, consider not only the visual aspects but also how they will hold up over time in your project’s specific environment. Proper surface treatment can lead to reduced maintenance and increased lifespan of the extrusions.

When selecting the right channel aluminum extrusion profiles for your project, understanding the material properties and finishes is essential for ensuring long-term durability. Aluminum itself is lightweight yet strong, making it an excellent choice for various construction and manufacturing applications. Additionally, aluminum is naturally resistant to corrosion, which can significantly extend the lifespan of the profiles when exposed to different environmental conditions.

Considering finishes, options such as anodizing or powder coating can enhance the durability of aluminum profiles. Anodizing increases resistance to scratching and corrosion by creating a thicker oxide layer on the surface, while powder coating provides a wide range of color choices and offers a protective barrier against physical wear and tear. Both finishes can help maintain the aesthetic appeal and structural integrity of your profiles over time.

Tips for choosing the right finish include assessing the environment in which the profiles will be used. If they will be exposed to harsh conditions, prioritize finishes that provide superior protection. Additionally, consider the desired appearance; if visual appeal is crucial, powder coating may be the better option. Always evaluate the specifications of your project and consult with material experts to ensure that the selected aluminum profiles meet both functional and aesthetic requirements.

When selecting channel aluminum extrusion profiles for your project, cost and availability are two fundamental factors that should guide your decision-making process. Understanding your budget constraints is crucial, as aluminum extrusions can vary significantly in price based on factors such as the complexity of the design, alloy specifications, and quantity ordered. It’s important to conduct a thorough cost analysis that encompasses not just the purchase price of the profiles, but also the associated costs, including machining, finishing, and delivery. By balancing quality and cost, you can ensure that your project remains financially viable without sacrificing the integrity of the final product.

Availability is equally significant, as delays in sourcing materials can hinder your project timeline. When evaluating aluminum profiles, consider lead times required for production and delivery. Engage with multiple suppliers to understand their stock levels and production capabilities. Some manufacturers may offer ready-to-ship profiles, while others might require longer lead times for custom designs. By prioritizing suppliers with reliable delivery schedules and consistent inventory, you can mitigate risks and maintain momentum in your project. Additionally, staying informed about market trends can help you anticipate potential fluctuations in availability, allowing for proactive adjustments to your sourcing strategy.

| Profile Type | Cost per Unit ($) | Availability (Lead Time in Weeks) | Weight per Meter (kg) | Application Suitability |

|---|---|---|---|---|

| Standard Channel | 5.00 | 2 | 2.3 | General Structural Uses |

| Heavy-Duty Channel | 8.50 | 4 | 4.5 | Industrial Applications |

| Lightweight Channel | 3.00 | 3 | 1.5 | Light Structural Use |

| U-Channel | 4.20 | 3 | 2.0 | Custom Supports |

| T-Channel | 6.00 | 5 | 3.0 | High-Strength Framework |