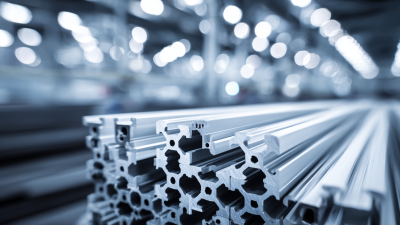

In the world of structural design and manufacturing, selecting the right material and profile is crucial for optimizing performance and efficiency. Standard Aluminum Extrusion Profiles have gained significant traction in various industries due to their lightweight, strength, and versatility. According to a report by the Aluminum Association, the aluminum extrusion market is projected to reach USD 50 billion by 2026, driven by rising demand in sectors such as construction, automotive, and consumer goods. With myriad profiles available, understanding the specific types of Standard Aluminum Extrusion Profiles—such as T-slots, angles, and channels—can greatly influence project outcomes. This article aims to provide a comparative analysis of these profiles, assisting professionals in determining which one best suits their unique needs and applications.

Aluminum extrusion profiles are widely used across various industries due to their lightweight, durability, and versatility. Key characteristics of these profiles include their ability to be customized into complex shapes, which allows for efficient integration in construction, automotive, and aerospace applications. According to a report by The Freedonia Group, the demand for aluminum extrusions is projected to reach $6.8 billion by 2025, driven primarily by the growing need for energy-efficient materials and lightweight structures.

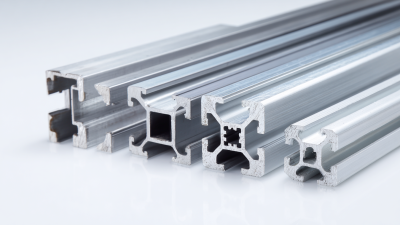

In practical applications, different profiles offer unique advantages. For instance, standard shapes like T-slots and angles provide excellent structural support, making them ideal for framework systems in manufacturing facilities. Meanwhile, custom profiles can be tailored to meet specific thermal, mechanical, or aesthetic requirements, as highlighted in a study from the Aluminum Association. This adaptability enables industries to enhance performance, reduce energy costs, and achieve environmental sustainability goals, showcasing the critical importance of selecting the right aluminum extrusion profile for any project.

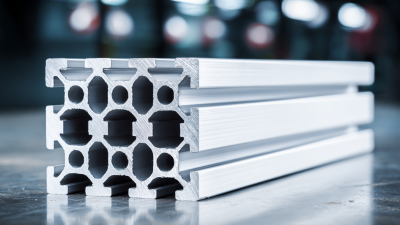

When choosing the right aluminum extrusion profile, evaluating strength and durability is paramount. Different profiles, such as square, rectangular, and round tubes, offer varying mechanical properties that can significantly impact performance in specific applications. For instance, square profiles generally provide better rigidity and are less prone to twisting under loads, making them ideal for structural components in construction. On the other hand, round tubes have excellent strength-to-weight ratios, which makes them suitable for applications requiring lightweight solutions without compromising durability.

Another crucial factor in profile selection is the material thickness and alloy composition, which directly influence the extrusion's resistance to wear and environmental factors. Profiles made from high-strength aluminum alloys can withstand harsh conditions, making them preferable for outdoor applications or industries like automotive and aerospace. Additionally, strength is often measured by the profile’s yield strength and tensile strength; understanding these metrics allows engineers and designers to select profiles that best meet their performance requirements without overspending on materials that may exceed their project needs.

When selecting aluminum extrusion profiles, balancing quality and cost is crucial for maximizing value. Recent market analysis indicates that while premium profiles often guarantee better durability and performance, their initial cost can be up to 30% higher than standard options. However, investing in quality can lead to long-term savings by reducing maintenance and replacement costs. For instance, studies have revealed that high-quality profiles can outperform cheaper alternatives in demanding applications by up to 50%, showcasing the importance of evaluating the lifecycle costs rather than just the initial price.

Tips: When assessing cost-effectiveness, consider the total cost of ownership, which includes installation, maintenance, and operational expenses. Opt for profiles that meet your specific requirements without unnecessary features, as customization can inflate costs. Additionally, consulting with suppliers about bulk purchase discounts can provide further savings, allowing you to stay within budget while ensuring that you select the best profile for your project. Analysis from industry reports suggests that companies that invest strategically in quality materials can reduce overall project costs by at least 15%.

When it comes to aluminum extrusions, customization plays a pivotal role in meeting specific project requirements. Understanding that no two projects are identical, manufacturers offer a variety of customization options, enabling businesses to tailor their aluminum profiles to their unique specifications. This flexibility includes adjustments in dimensions, shapes, and surface finishes, which can significantly enhance the performance and aesthetics of the end product.

For instance, clients can choose from a range of alloy compositions to ensure their extrusions are not only lightweight but also possess the strength and durability needed for their applications. Additional customization options such as anodizing, powder coating, or even painting allow for an array of colors and textures, making it easier to integrate the extrusions into existing designs while also improving corrosion resistance. With these bespoke solutions, companies can optimize their operations, streamline assembly processes, and ultimately create products that align perfectly with their vision and functional requirements.

| Profile Type | Weight (kg/m) | Load Capacity (kN) | Customization Options | Common Applications |

|---|---|---|---|---|

| Standard 20 Series | 1.5 | 5.0 | Variety of finishes, lengths, and connectors | Workstations, modular framing |

| Standard 30 Series | 2.0 | 8.0 | Powder coating, anodizing options | Machinery frames, guards |

| Standard 40 Series | 2.5 | 10.0 | Custom machining, surface treatments | Heavy machinery, construction frames |

| Standard 45 Series | 3.0 | 12.0 | Anodizing, custom lengths | Automotive components, frames |

The aluminum extrusion industry is increasingly embracing sustainability, driven by both regulatory pressures and consumer demand for eco-friendly practices. A report from the Aluminum Association indicates that recycled aluminum uses 95% less energy compared to primary aluminum production, significantly reducing the carbon footprint associated with extraction and processing. By incorporating recycled materials into their processes, manufacturers not only conserve natural resources but also contribute to a circular economy, which is becoming increasingly relevant in various industries.

Furthermore, innovative practices such as closed-loop recycling systems and energy-efficient extrusion methods are gaining traction. According to a recent study by the International Aluminum Institute, implementing energy-efficient technologies can reduce greenhouse gas emissions by up to 30%. Such advancements not only enhance the sustainability profile of aluminum extrusions but also provide a competitive edge in a market that is leaning towards responsible sourcing. By choosing suppliers who prioritize eco-friendly materials and practices, businesses can align with global sustainability goals while meeting the growing consumer expectations for environmentally responsible products.