When it comes to selecting the right materials for your construction or renovation project, the choice of Aluminum Profiles for Windows and Doors plays a critical role in both aesthetics and functionality. Aluminum profiles are renowned for their durability, lightweight nature, and resistance to corrosion, making them a preferred option among architects and builders alike. However, with the plethora of options available in the market, choosing the right aluminum profiles can be daunting. This guide aims to simplify the decision-making process by providing essential tips that will help you make informed choices tailored to your specific needs.

From understanding the different types of aluminum profiles to recognizing the importance of thermal efficiency and design compatibility, this article will equip you with the knowledge required to enhance the performance and appearance of your windows and doors. Let’s dive into the key considerations that will ensure you select the perfect aluminum profiles for your project.

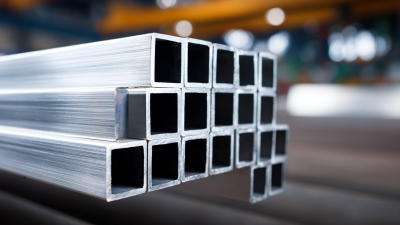

When selecting aluminum profiles for windows and doors, assessing their durability is crucial for ensuring long-term performance. One key factor is the thickness of the aluminum. Thicker profiles tend to withstand external stress better, resisting warping and bending over time. Additionally, consider the quality of the alloy used; high-grade alloys are specifically designed to endure harsh weather conditions without compromising their structural integrity.

Another important aspect is the surface treatment applied to the profiles. Anodizing, for example, not only enhances aesthetic appeal but also increases corrosion resistance, which is vital for outdoor applications. It is also beneficial to review warranty information and manufacturer reputation as they often reflect product reliability.

Tip: Always request samples of the aluminum profiles to evaluate their feel and weight; durable aluminum will generally be heavier and offer a solid construction. Additionally, look for profiles that come with a certification ensuring they meet industry standards for strength and longevity. This will provide peace of mind that your investment will hold up well over time.

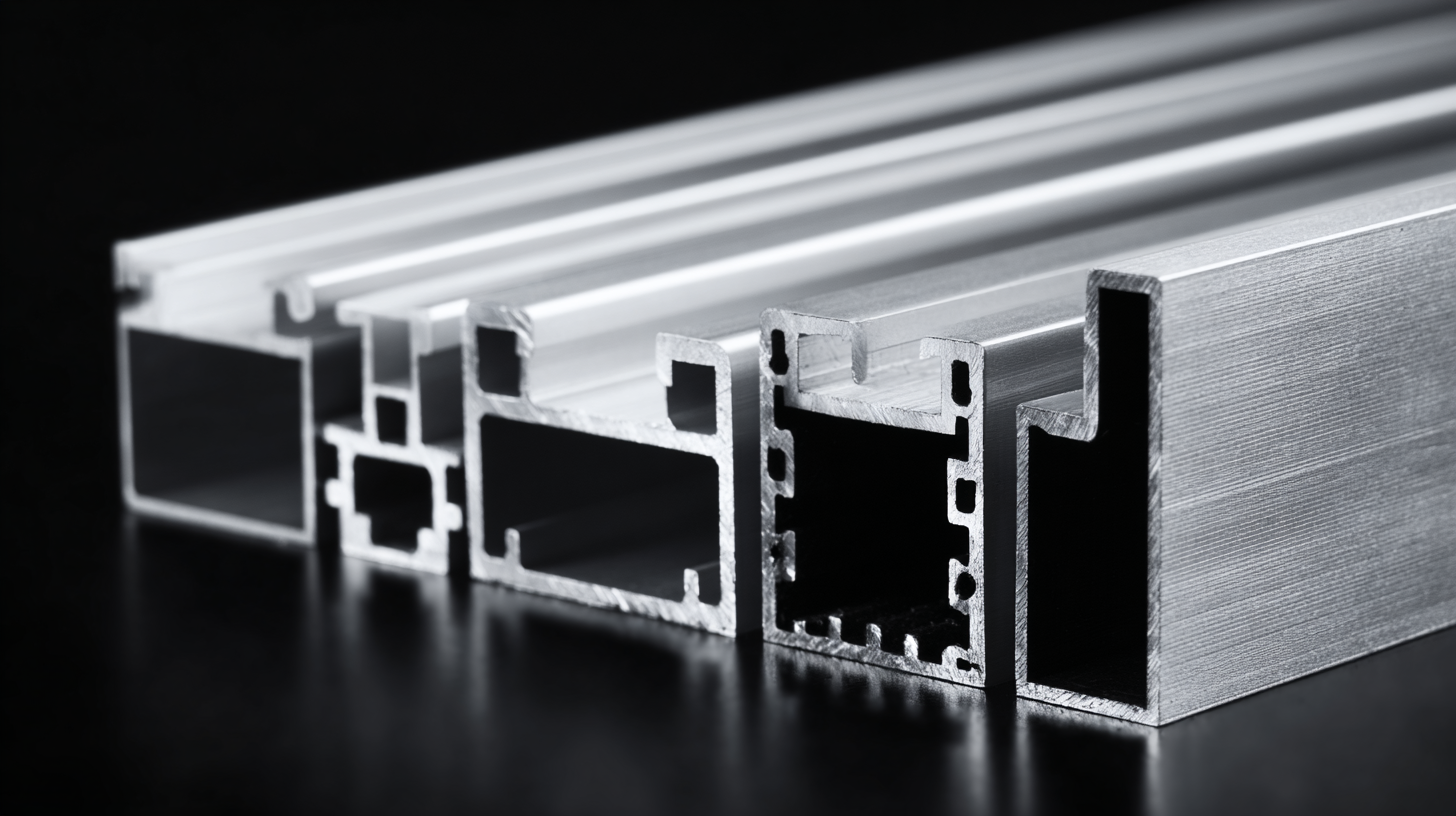

When selecting aluminum profiles for windows and doors, thermal performance is a critical factor that can greatly influence energy efficiency and comfort in buildings. According to the National Institute of Standards and Technology (NIST), nearly 30% of energy used for heating and cooling in the average home is due to heat loss through windows and doors. Therefore, choosing the right aluminum profile can contribute significantly to reducing energy consumption.

One key element that affects thermal performance is the presence of thermal breaks within the aluminum profiles. Research from the Aluminum Association indicates that profiles with thermal breaks can achieve U-values as low as 0.15 W/m²K, which is essential for meeting modern building codes and energy efficiency standards. Additionally, advancements in insulation materials have allowed for even better performance; the use of polyamide or polyurethane thermal barriers can increase insulation efficiency by up to 50%. Selecting profiles with these features not only enhances energy efficiency but also contributes to the overall lifecycle sustainability of the building, making it a wise investment for homeowners and builders alike.

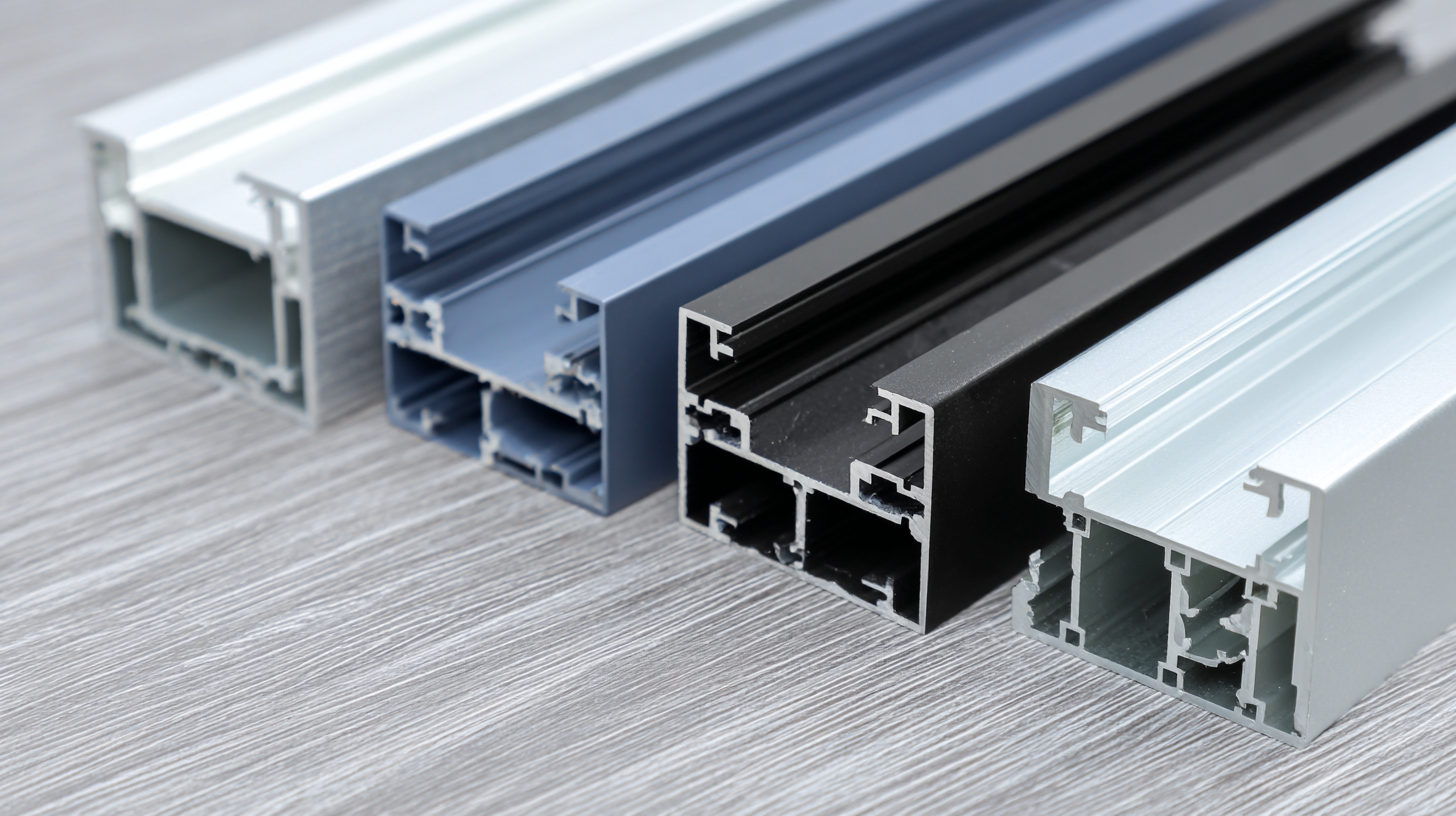

When selecting aluminum profiles for windows and doors, understanding the importance of aluminum alloy selection is crucial for maintaining profile integrity. The choice of aluminum alloy affects both the performance and longevity of the final product. According to a report from the Aluminum Association, using high-quality alloys can improve resistance to corrosion and enhance thermal performance significantly. This highlights the necessity of selecting profiles that meet specific environmental conditions and structural requirements.

When evaluating aluminum profiles, consider these tips:

By carefully selecting the right aluminum alloys and adhering to these tips, you can ensure your windows and doors will possess the strength, efficiency, and aesthetics required for any building project.

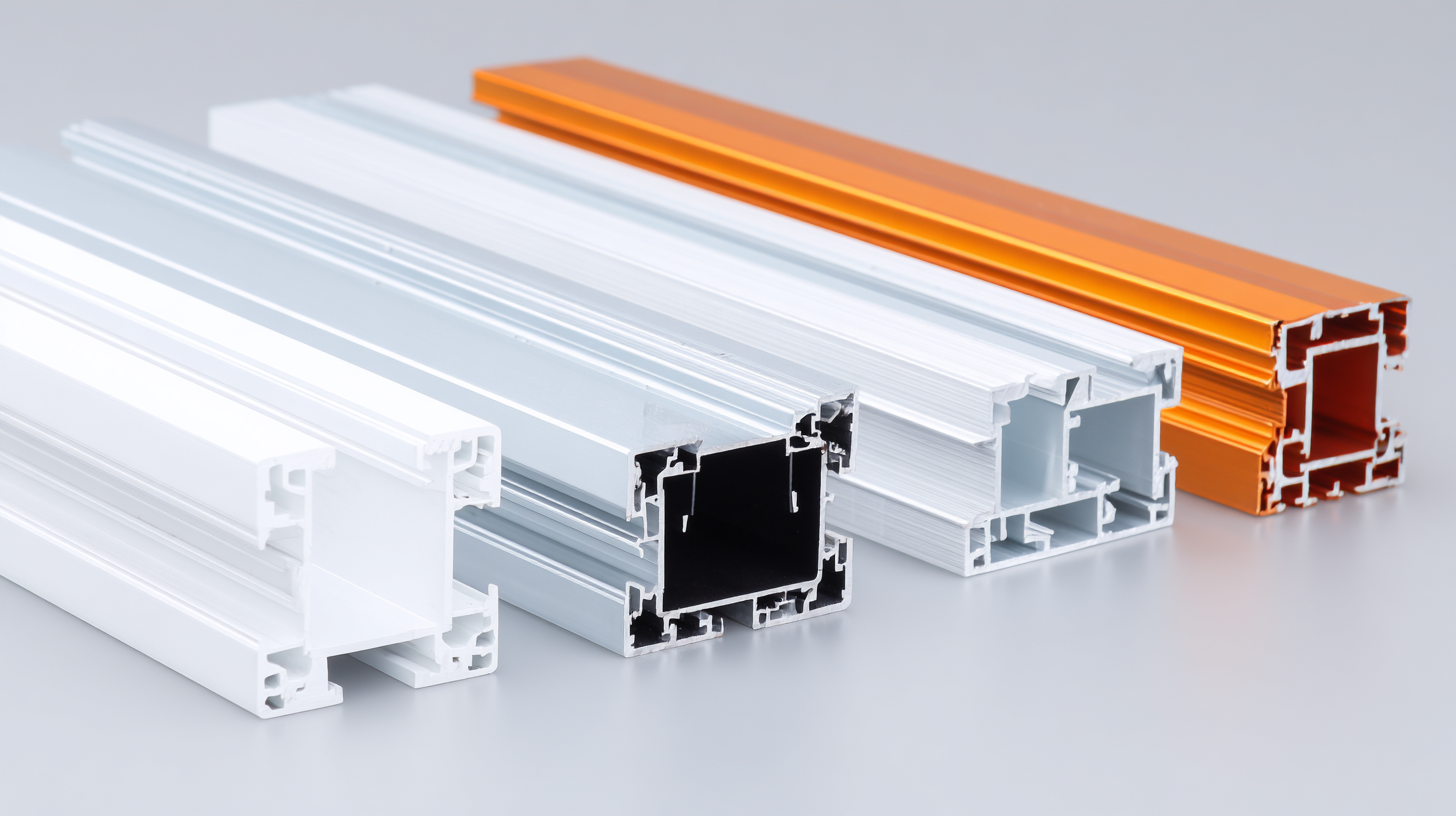

When selecting aluminum profiles for windows and doors, the choice of surface treatment is crucial for enhancing longevity and reducing maintenance.

Anodizing, powder coating, and painting are common treatments that add a protective layer to the aluminum, shielding it from environmental factors such as moisture, UV rays, and corrosion.

Anodizing increases surface hardness and resistance to wear, while powder coating offers a wide range of colors and finishes, ensuring that aesthetics are not sacrificed for durability.

Furthermore, these surface treatments significantly impact the overall maintenance required over time. Aluminum profiles with high-quality finishes tend to require less frequent cleaning and upkeep, allowing homeowners to enjoy their installations without worrying about constant repairs or repainting.

When choosing aluminum profiles, considering the specific surface treatment can help ensure that your investment remains appealing and functional for many years to come.

When selecting aluminum profiles for windows and doors, understanding the balance between cost-effectiveness and quality is crucial for making informed decisions. According to a report from the Aluminum Association, high-quality aluminum profiles can enhance energy efficiency and longevity, potentially reducing lifecycle costs by up to 30%. Investing in superior materials not only improves aesthetic appeal but also contributes to reduced maintenance expenses over time.

Additionally, industry data suggests that while budget options may seem attractive upfront, they often lead to increased costs due to frequent replacements or repairs. A study conducted by the National Institute of Building Sciences found that utilizing high-performance aluminum profiles can yield significant savings in energy consumption—up to 20% in heating and cooling costs. Therefore, when analyzing both quality and budget, it's essential to consider the long-term financial implications of your aluminum profile choices, ensuring that they align with your investment goals.

| Profile Type | Thickness (mm) | Weight (kg/m) | Thermal Conductivity (W/m·K) | Estimated Cost ($/m) | Durability (Years) |

|---|---|---|---|---|---|

| Standard Profile | 1.2 | 1.5 | 205 | 15 | 20 |

| Reinforced Profile | 1.5 | 2.0 | 180 | 20 | 25 |

| Thermal Break Profile | 1.6 | 2.3 | 150 | 25 | 30 |

| Architectural Profile | 2.0 | 3.0 | 100 | 30 | 35 |