When it comes to sourcing high-quality extruded aluminum profiles globally, navigating the complexities of international markets can be a daunting task. With the increasing demand for innovative designs and durable materials across various industries, understanding how to effectively source these profiles is essential for manufacturers and designers alike. In this blog, we will explore seven essential tips that will guide you through the process of finding reliable suppliers, ensuring that you receive top-notch extruded aluminum profiles that meet your specifications and standards. From evaluating supplier credentials to optimizing logistics, these strategies will equip you with the knowledge needed to make informed sourcing decisions, ultimately enhancing the quality and efficiency of your projects. Join us as we delve into the world of extruded aluminum profiles and empower your sourcing capabilities.

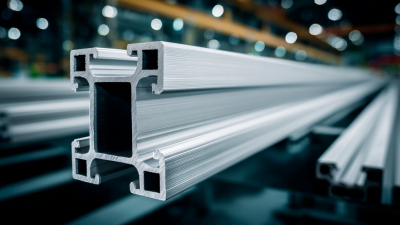

Extruded aluminum profiles are versatile components widely used across various industries such as construction, automotive, and aerospace. Their unique manufacturing process allows for the creation of complex shapes and designs that can be tailored to specific needs. By forcing aluminum through a die, manufacturers can produce profiles with consistent cross-sections and a smooth finish, making them ideal for applications ranging from structural frames to decorative elements.

One of the key advantages of extruded aluminum profiles is their lightweight yet durable nature. This combination makes them an ideal choice for products that require strength without adding excessive weight. Additionally, aluminum is naturally resistant to corrosion, enhancing the longevity of products used in outdoor environments. By understanding the different grades and finishes available, businesses can select the right profiles that not only meet their functional requirements but also align with aesthetic preferences, ensuring both performance and visual appeal in their applications.

| Tip Number | Tips | Key Considerations | Applications |

|---|---|---|---|

| 1 | Research Global Suppliers | Evaluate their reputation and quality certifications. | Industries such as automotive and aerospace. |

| 2 | Assess Material Standards | Ensure compliance with international standards like ASTM. | Construction and building frameworks. |

| 3 | Request Samples | Investigate the quality and finish of the product. | Consumer electronics casings. |

| 4 | Evaluate Production Capacity | Check the supplier's ability to meet your order volumes. | Custom projects in various sectors. |

| 5 | Understand Lead Times | Plan your sourcing based on realistic delivery timelines. | Manufacturing assembly lines. |

| 6 | Consider Pricing and Payment Terms | Negotiate terms that benefit both parties. | General construction materials. |

| 7 | Establish Communication Channels | Maintain clear and open lines of communication. | Various applications across industries. |

When sourcing high-quality extruded aluminum profiles globally, identifying key suppliers is crucial for both cost efficiency and product integrity. According to the "Aluminum Extrusions Market Report 2022," the global market for aluminum extrusions is projected to reach $90 billion by 2027, with a compound annual growth rate (CAGR) of 4.5%. This growth indicates increasing demand for quality materials, making the selection of reliable manufacturers paramount. To optimize sourcing, businesses should thoroughly evaluate potential suppliers based on industry certifications, production capabilities, and their track record in delivering consistent quality.

Additionally, a recent study from the International Aluminum Institute reveals that over 75% of aluminum producers are focused on sustainability and reducing the carbon footprint in their operations. When assessing suppliers, it is essential to consider their commitment to sustainable practices, as this can significantly impact the quality and environmental viability of the product. By leveraging comprehensive data and insights from industry reports, buyers can make informed decisions that align with quality standards and environmental sustainability, ensuring a reliable supply chain for extruded aluminum profiles.

Ensuring the integrity of extruded aluminum profiles is crucial for industries that demand superior performance and durability. According to a recent report from the Aluminum Association, the global market for aluminum extrusion is projected to reach $90 billion by 2026, underscoring the importance of quality control throughout the sourcing process. Implementing best practices in quality control not only safeguards material integrity but also enhances the overall value of the final products.

Key quality control practices include rigorous testing methods such as tensile strength evaluations and surface inspections. The International Organization for Standardization (ISO) emphasizes the role of standardized metrics to assess material performance, suggesting that suppliers should be ISO 9001 certified to validate their quality management systems. Moreover, leveraging advanced technologies like spectrometry for material composition analysis can prevent sourcing subpar aluminum that may compromise structural integrity. As industries increasingly rely on extruded aluminum, prioritizing thorough quality control protocols becomes essential for maintaining competitive advantage and customer trust.

When it comes to global sourcing of high-quality extruded aluminum profiles, negotiating contracts is a pivotal step that can significantly affect your success. Understanding the nuances of negotiation can help you secure favorable terms while mitigating risks associated with international procurement. Begin by establishing clear objectives and benchmarks for performance; this clarity will serve as the foundation for your discussions. Moreover, cultivating a good rapport with suppliers can lead to more collaborative negotiations, fostering trust and transparency throughout the process.

Utilizing effective negotiation strategies is essential for achieving a win-win outcome. Consider exploring options such as volume discounts, flexible payment terms, and delivery timelines that align with your operational needs. It’s also critical to address potential risks upfront, discussing quality assurance measures and penalties for non-compliance to ensure that both parties are aligned. By approaching negotiations with a combination of assertiveness and openness, you'll not only secure a fair contract but also build long-lasting relationships that can lead to future collaborations in the ever-competitive field of aluminum sourcing.

Shipping and logistics play a crucial role in ensuring the timely delivery of high-quality extruded aluminum profiles globally. In 2021, the global aluminum extrusion market was valued at approximately $71 billion, with expectations to reach $95 billion by 2028, indicating a growing demand for efficient supply chain management. To optimize delivery processes, companies must consider several key factors, including transportation modes, packaging, and inventory management. Utilizing a combination of air and sea freight can significantly reduce transit times while balancing costs, ensuring that profiles arrive in optimal condition.

Furthermore, implementing advanced logistics solutions such as real-time tracking systems can enhance operational efficiency. According to a report by McKinsey, companies that adopt advanced tracking technologies see a 15% improvement in shipping accuracy and a reduction in delivery delays by up to 20%. Additionally, proper packaging is essential to protect extruded aluminum profiles from damage during transit. According to industry standards, utilizing custom-designed packaging can reduce the risk of damage and ensure products meet international shipping requirements, leading to improved customer satisfaction and a stronger global presence in the competitive market of aluminum profiles.