Extruded Aluminum Enclosure Profiles have gained significant traction in various industries due to their excellent mechanical properties and versatile applications. According to a recent market analysis by ResearchAndMarkets, the global aluminum extrusion market is projected to reach $76.2 billion by 2027, highlighting the increasing demand for these profiles in sectors such as telecommunications, electronics, and manufacturing. The lightweight yet sturdy nature of extruded aluminum makes it an ideal choice for creating custom enclosures that provide protection against environmental factors while maintaining optimal thermal management.

Dr. John Phillips, an industry expert in material science, states, “The use of extruded aluminum enclosure profiles revolutionizes the way we design systems, offering not only durability but also enhanced aesthetic appeal.” His insights underline the significance of these profiles, which facilitate efficient heat dissipation and structural integrity, vital for ensuring the longevity and reliability of electronic equipment. With the growing trend towards sustainable manufacturing processes, businesses are increasingly acknowledging the eco-friendly attributes of aluminum, further strengthening its market presence.

In conclusion, the key benefits of Extruded Aluminum Enclosure Profiles, including their lightweight construction, resistance to corrosion, and customization potential, make them an essential component in modern engineering solutions. As industries continue to evolve, the demand for innovative enclosure designs will only intensify, paving the way for advancements in extruded aluminum technology.

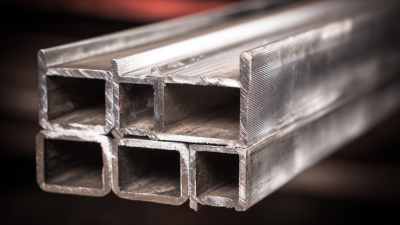

Extruded aluminum enclosure profiles are structural components created through a process that shapes aluminum alloys into specific cross-sectional forms. This manufacturing technique offers exceptional versatility, allowing for intricate designs that cater to various applications across multiple industries. According to a recent market report by Smithers Pira, the global aluminum market is projected to grow by 4.3% annually, reflecting the increased demand for lightweight and durable materials in construction, electronics, and transportation.

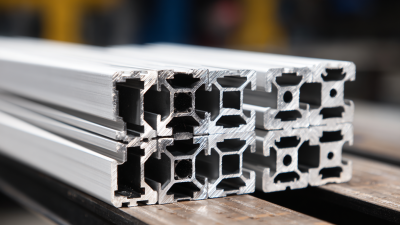

One of the key applications of extruded aluminum enclosure profiles is in the production of electronic housings and casings. The lightweight nature of aluminum combined with its excellent thermal conductivity makes it an ideal choice for managing heat dissipation in electronic devices. Furthermore, the natural resistance of aluminum to corrosion provides longevity and reliability, making it suitable for both indoor and outdoor applications. As noted in a study published by Research and Markets, the growing trend towards miniaturization and automation in manufacturing has further spurred the demand for customized extrusion designs, ensuring adaptability to the evolving needs of various sectors.

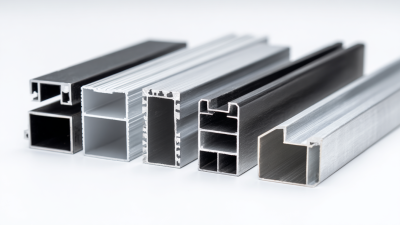

These profiles also find utility in architectural applications, where aesthetics and functionality must coexist. The ability to create custom shapes enhances design flexibility while maintaining structural integrity. The extrusion process allows for the integration of features such as mounting points and channels, resulting in streamlined installation and increased efficiency. With the rising emphasis on sustainable building practices, the recyclability of aluminum serves as an additional benefit, aligning with the growing demand for environmentally friendly materials in modern construction projects.

| Dimension | Details |

|---|---|

| Material | Aluminum alloy (6063, 6061) |

| Thickness | 1.0 mm - 5.0 mm |

| Profiles Types | T-slot, U-channel, L-shape, H-shape |

| Surface Treatment | Anodizing, Powder Coating |

| Applications | Electronics housing, Machinery frames, Custom enclosures |

| Benefits | Lightweight, Corrosion-resistant, Customizable, Easy assembly |

| Thermal Conductivity | Excellent thermal dissipation |

| Weight per meter | Variable, generally around 0.5 kg - 3 kg |

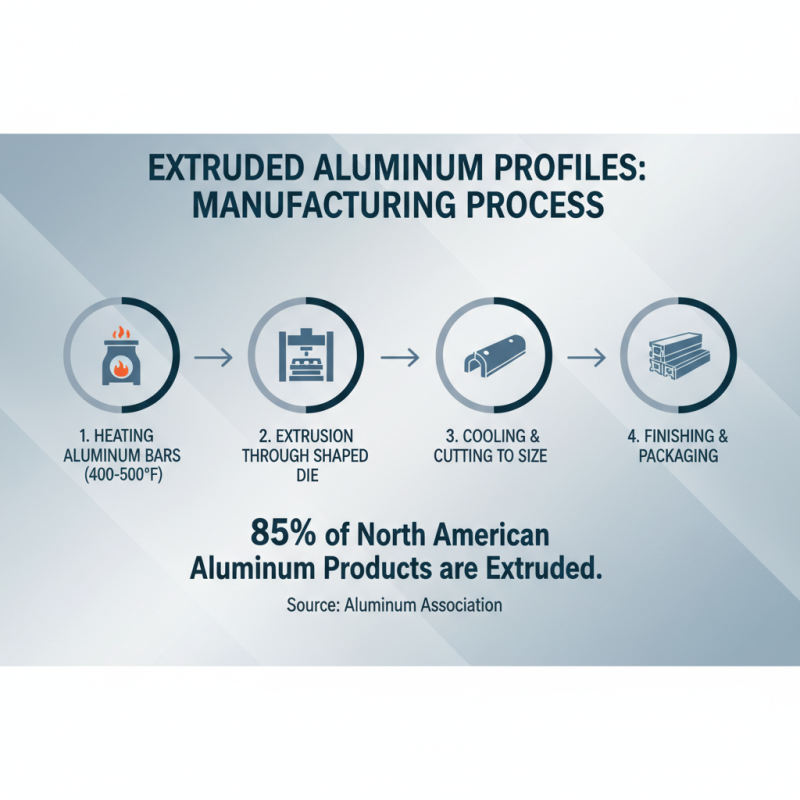

The manufacturing process for extruded aluminum profiles involves several key steps that contribute to the durability and versatility of these enclosures. The primary method begins with the heating of aluminum bars to a malleable state, typically around 400-500 degrees Fahrenheit. This allows the aluminum to be forced through a shaped die under high pressure, creating a continuous profile that can be cut to size. According to the Aluminum Association, extrusion is responsible for producing around 85% of all aluminum products in North America, underscoring its importance in the industry.

Once extruded, the profiles undergo several finishing processes, including anodizing, painting, or powder coating. Anodizing enhances corrosion resistance and improves the aesthetic appeal of the aluminum, while powder coating offers a durable finish that can withstand environmental stresses. Recent reports indicate that the global aluminum extrusion market is projected to reach approximately $45 billion by 2025, driven by the growing demand from industries such as construction, automotive, and electrical. These processes not only increase the longevity of the profiles but also enable customization to meet specific design requirements, making extruded aluminum enclosures an ideal choice for a variety of applications.

Aluminum enclosures, particularly those utilizing extruded profiles, are becoming increasingly popular due to their remarkable durability and lightweight properties. The inherent strength of aluminum allows these enclosures to withstand harsh environmental conditions, making them ideal for both indoor and outdoor applications. The resistance to corrosion adds to their longevity, ensuring that components housed within remain protected against elements that could otherwise cause damage over time.

Another significant advantage of aluminum enclosures is their lightweight nature compared to alternatives made from materials like steel. This reduced weight not only aids in easier handling and installation but also lowers transportation costs. Businesses can save on shipping expenses while ensuring that their products are secure. Moreover, the lightweight properties of aluminum can contribute to overall energy efficiency in applications where weight reduction is critical, such as in aerospace or automotive industries.

**Tips:** When selecting an aluminum enclosure, consider the specific environmental conditions it will face. For outdoor applications, look for options with additional protective coatings. Additionally, assess the enclosure's design features, such as mounting options and internal configurations, to ensure ease of access and maintenance.

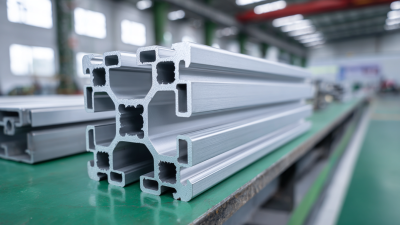

Extruded aluminum enclosure profiles are increasingly recognized for their cost-efficiency and sustainability, making them a preferred choice in various industries. The manufacturing process of extruding aluminum involves shaping the metal by forcing it through a die, resulting in customizable profiles that suit diverse applications. This method reduces material waste, as it utilizes aluminum more effectively than traditional machining processes. Additionally, the inherent properties of aluminum, such as its high strength-to-weight ratio, allow designers to create lighter enclosures that still provide robust protection, minimizing shipping and handling costs.

Sustainability is another significant advantage of extruded aluminum solutions. Aluminum can be recycled indefinitely without losing its properties, contributing to a circular economy that reduces the demand for new raw materials. The energy required to recycle aluminum is considerably lower than that needed for primary production, thus decreasing the overall carbon footprint. Companies that prioritize these sustainable practices not only enhance their brand image but also comply with increasing regulatory demands for environmentally friendly solutions. By opting for extruded aluminum profiles, organizations can achieve economically viable and environmentally responsible designs.

Recent trends in extruded aluminum enclosure design reflect a significant shift towards sustainability and enhanced functionality. The demand for lightweight and durable materials has driven innovations that prioritize energy efficiency and environmental impact. According to a report by Grand View Research, the global aluminum extrusion market is projected to reach $98.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.0%. This growth signifies a burgeoning interest in eco-friendly materials and manufacturing processes within the industry.

Additionally, advancements in design technologies, such as modular construction and 3D modeling, are enabling manufacturers to create custom solutions that meet specific client needs. The use of computer-aided design (CAD) software allows for greater precision and flexibility in creating enclosure profiles, leading to optimized performance and reduced waste. Industry experts emphasize that integrating smart technology into extruded aluminum enclosures is becoming increasingly common. This includes the incorporation of sensors and IoT capabilities, which add value by providing real-time monitoring and enhanced security features. As the market continues to evolve, these innovations highlight the industry's commitment to adapt and thrive in a competitive landscape, ensuring that extruded aluminum enclosures remain at the forefront of modern engineering solutions.