When it comes to designing and constructing innovative projects, the choice of materials plays a critical role in ensuring structural integrity and aesthetic appeal. Among the myriad of options available, Aluminum Corner Extrusion Profiles stand out as a preferred choice for architects and engineers alike. According to a recent market report by ResearchAndMarkets, the global aluminum extrusion market is projected to reach $115 billion by 2025, underscoring the material's growing significance in various applications, from construction to automotive industries. These profiles not only provide strength and durability but also offer versatility in design, making them ideal for a wide range of applications. This guide aims to navigate you through the essential considerations and best practices for selecting the right Aluminum Corner Extrusion Profiles for your projects, ensuring optimal performance and satisfaction.

When embarking on a design project, understanding the significance of aluminum corner extrusion profiles cannot be overstated. These profiles play a crucial role in ensuring structural integrity and aesthetic appeal, making them an essential consideration for architects and designers alike. The precision that comes with aluminum extrusions allows for seamless connections at critical junctions, which not only enhance the strength of the build but also contribute to the overall design narrative.

Recent discussions on materiality, such as those observed in Herzog & de Meuron’s Tai Kwun Center, highlight how the choice of materials can define the character and functionality of a project. By selecting high-quality aluminum corner extrusions, designers can ensure longevity and resilience in their structures, honoring heritage while embracing modernity. This blend of aesthetics and practicality is vital in creating spaces that resonate with users, ensuring that every detail, down to the corner profiles, supports the intended design vision.

When selecting aluminum corner extrusion profiles for your projects, it's essential to consider several key factors that can significantly impact the performance and aesthetic appeal of your final product. According to a report by the Aluminum Association, the global demand for aluminum extrusion is expected to reach 22 million metric tons by 2025, reflecting the material's increasing popularity due to its lightweight yet durable properties. This trend highlights the necessity of choosing the right profiles to ensure structural integrity and longevity, especially in applications where flexibility and strength are paramount.

Another critical consideration is the profile's design and dimensions, which should align with the specific requirements of your project. Research from the International Aluminum Institute indicates that well-designed aluminum extrusions can lead to a 30% reduction in material waste, enhancing both sustainability and cost-effectiveness. By focusing on the right dimensions and design, manufacturers can optimize their production processes while minimizing expenditures, ensuring that the selected aluminum corner profiles meet both performance criteria and budget constraints.

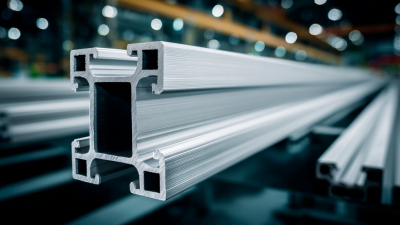

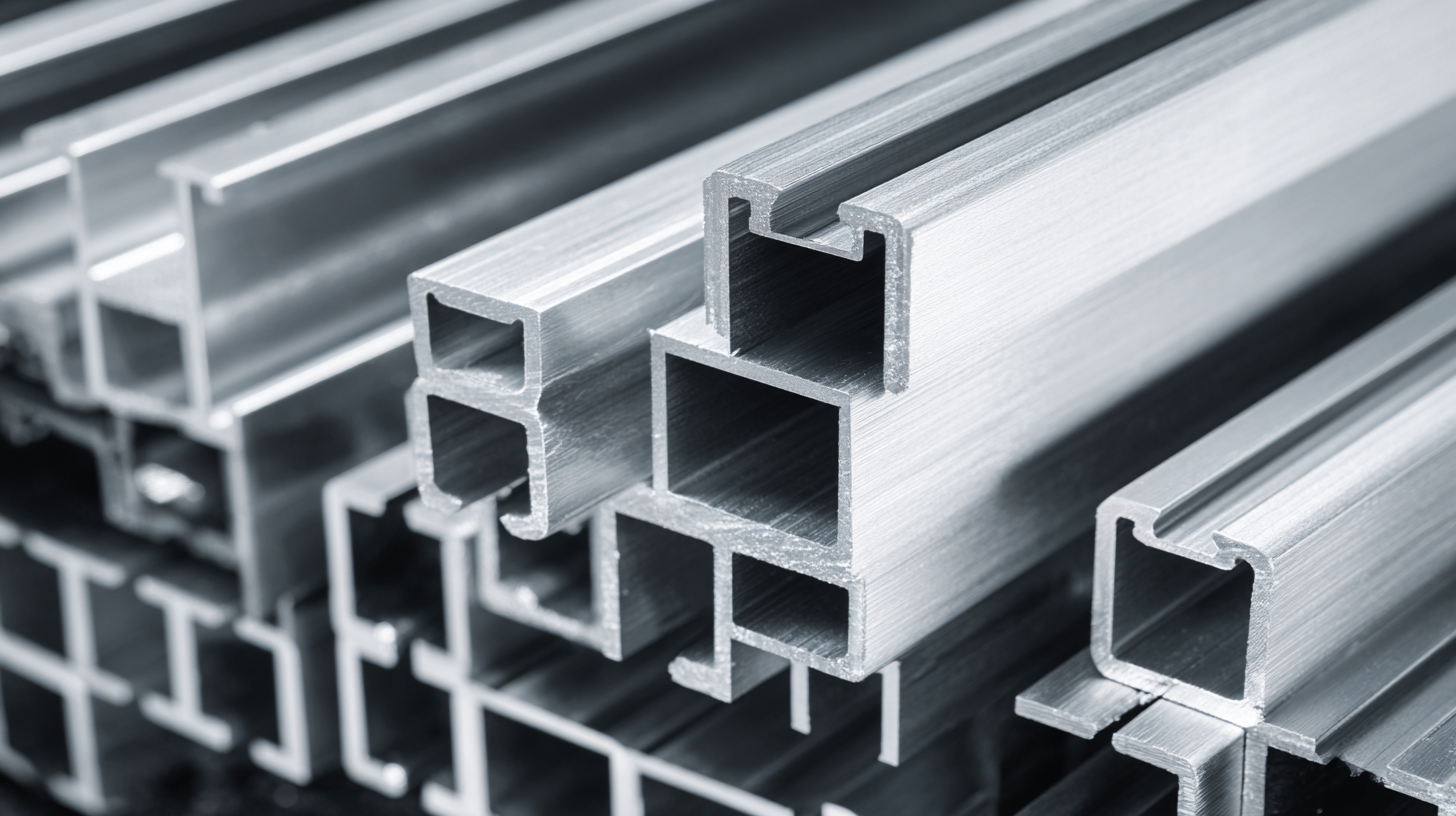

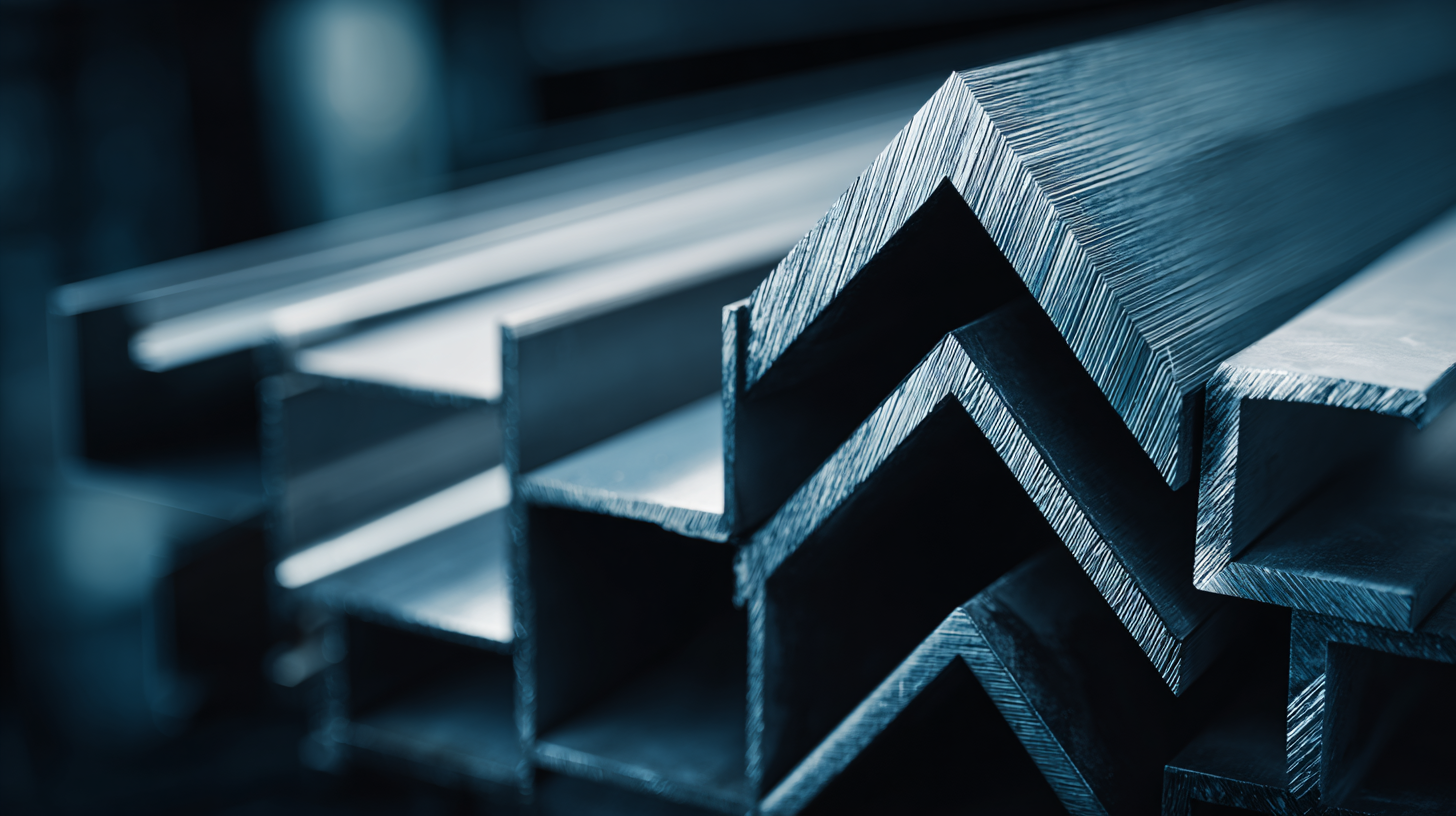

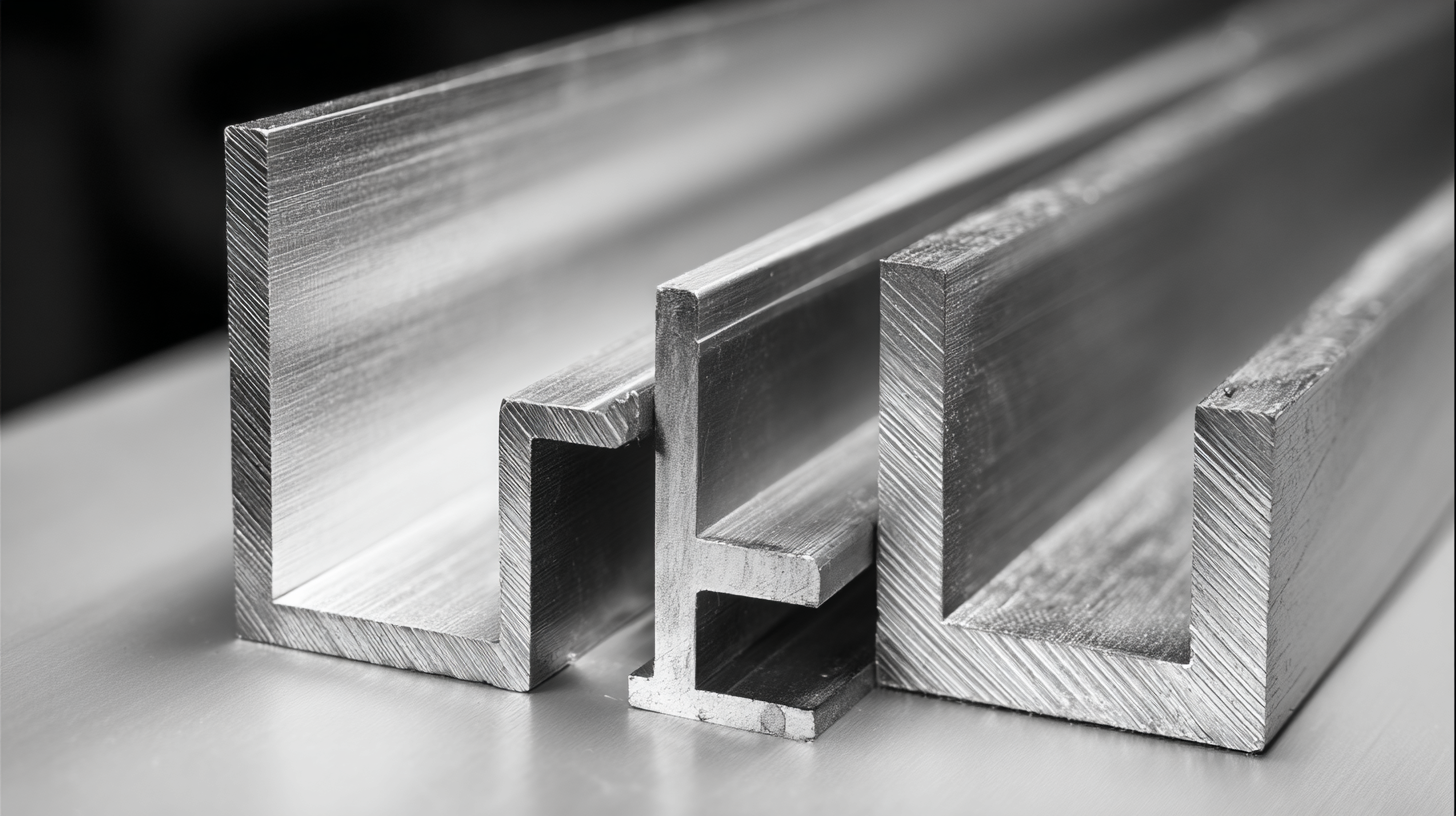

When selecting aluminum corner extrusion profiles for your projects, understanding the different types available is crucial for ensuring optimal functionality and aesthetic appeal. There are several common types of aluminum corner profiles, each tailored to specific applications and structural needs.

For instance, L-shaped corner extrusions are often used for framing and shelving, providing stability while allowing for easy assembly in various constructions. Their versatility makes them a favorite in both DIY projects and professional applications.

For instance, L-shaped corner extrusions are often used for framing and shelving, providing stability while allowing for easy assembly in various constructions. Their versatility makes them a favorite in both DIY projects and professional applications.

Another popular option is the U-shaped corner extrusion, which is particularly useful in creating enclosures or borders. Its design allows for efficient integration into panels, making it ideal for applications ranging from signage to protective covers. Additionally, T-shaped profiles provide robust joint connections in multi-directional assemblies, often employed in furniture manufacture or architectural designs. By understanding these different types of aluminum corner extrusion profiles, you can make informed decisions that enhance the durability and design of your projects.

When it comes to sourcing high-quality aluminum corner extrusion profiles for your projects, there are several key factors to consider to ensure you make the best choice. First and foremost, identify your specific project requirements. Understand the dimensions, design standards, and functionality needed for your application. This clarity will help you filter out unsuitable options and narrow down your search effectively.

Another crucial tip is to evaluate the supplier's reputation. Look for manufacturers with a proven track record in producing durable aluminum extrusions. Reading customer reviews and testimonials can provide insight into their product quality and customer service. Additionally, check if the supplier adheres to industry standards and certifications, as this often reflects their commitment to quality.

Finally, consider the sourcing options available to you. Whether you choose local suppliers or international manufacturers, weigh the benefits of price versus quality. Establishing a good relationship with your supplier can lead to better deals and more reliable service over time. Don't hesitate to ask for samples to assess the material's quality before making a bulk purchase.

When selecting aluminum corner extrusion profiles for your projects, it’s crucial to avoid common pitfalls that can lead to inefficiencies and increased costs. A frequent mistake is underestimating the importance of loading conditions. Many designers choose profiles based solely on aesthetics rather than evaluating the mechanical properties required for their intended application. Understanding the load-bearing capabilities of different profiles ensures you're not left with a design that compromises structural integrity.

Another common error is disregarding the manufacturing tolerances of the extrusions. Not every aluminum provider maintains the same standards, and variations can affect how well the profiles fit together during assembly. This oversight can result in alignment issues that not only delay the project but may also necessitate costly adjustments or rework. Always ensure to verify the specifications with your supplier to avoid these complications, emphasizing the need for precise dimensions in your design plans.