In today's fast-paced manufacturing sector, the significance of Extruded Aluminum Profiles cannot be overstated. According to a recent study by the Aluminum Association, the demand for aluminum in the global market is projected to reach 102 million tons by 2025, with extruded profiles making up a considerable segment due to their versatility and lightweight nature. These profiles play a crucial role in diverse industries, from aerospace to construction, providing both structural integrity and aesthetic appeal. Moreover, a report from MarketsandMarkets indicates that the global extrusion market is anticipated to grow at a CAGR of 6.2% during the forecast period, underlining the increasing reliance on this manufacturing method. As we delve into the essential aspects of Extruded Aluminum Profiles, it becomes clear that they not only contribute to enhanced productivity and efficiency but also pave the way for innovative solutions in modern manufacturing practices.

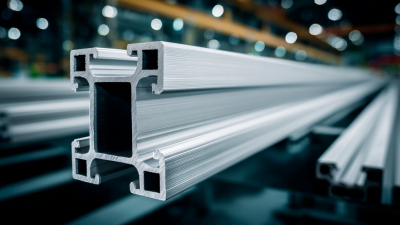

Extruded aluminum profiles play a vital role in modern manufacturing, offering a perfect blend of strength, flexibility, and lightweight properties. The manufacturing process involves forcing heated aluminum through a shaped opening in a die, resulting in complex cross-sectional shapes. This technique allows manufacturers to create components that are not only structurally robust but also tailored to specific applications, from architectural frames to intricate electronic housings.

The versatility of extruded aluminum profiles is further enhanced by the ability to modify their properties post-extrusion. Techniques such as anodizing and powder coating can improve corrosion resistance, enhance aesthetic appeal, and increase surface durability. Additionally, the continuous nature of the extrusion process facilitates mass production, leading to reduced waste and cost efficiencies. As industries strive for more sustainable and efficient practices, extruded aluminum profiles emerge as a smart choice, marrying practicality with innovation in design and functionality.

Extruded aluminum profiles have become a pivotal component in modern manufacturing, offering a myriad of benefits that enhance production efficiency and product quality. According to a report by the Aluminum Association, the global aluminum extrusion market is projected to reach over $40 billion by 2025, reflecting the material's growing significance in various sectors, including automotive, construction, and aerospace. The versatility of extruded aluminum enables manufacturers to produce lightweight yet strong components, thus improving fuel efficiency and reducing overall production costs.

One of the key advantages of using extruded aluminum profiles lies in their design flexibility. Manufacturers can create complex shapes tailored to specific applications, optimizing both functionality and aesthetics. A study published by the International Journal of Advanced Manufacturing Technology noted that the precision of aluminum extrusion can reduce material waste by up to 25%, a crucial factor in today’s eco-conscious production landscape. Furthermore, aluminum's resistance to corrosion and its recyclability contribute to sustainable manufacturing practices, aligning with industry trends favoring environmentally friendly materials. This combination of factors positions extruded aluminum profiles as essential in driving innovation and competitiveness in modern manufacturing processes.

| Benefit | Description | Applications |

|---|---|---|

| Lightweight | Aluminum is significantly lighter than other metals, allowing for easier handling and reduced transportation costs. | Aerospace, automotive, and furniture manufacturing. |

| Corrosion Resistance | Extruded aluminum naturally forms a protective oxide layer, preventing rust and corrosion. | Construction, marine applications, and outdoor furnishings. |

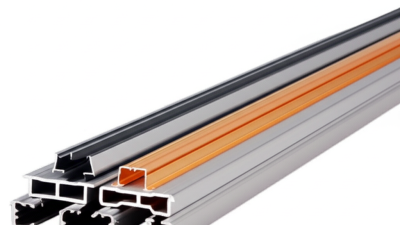

| Customization | Various shapes, sizes, and finishes can be produced to meet specific design requirements. | Electronics, packaging, and custom furniture design. |

| Sustainability | Aluminum is recyclable, making it an eco-friendly choice in manufacturing. | Building materials, automotive components, and consumer products. |

| Strength-to-Weight Ratio | Provides high strength while maintaining a low weight, essential for various structural applications. | Transportation, structural supports, and machinery frames. |

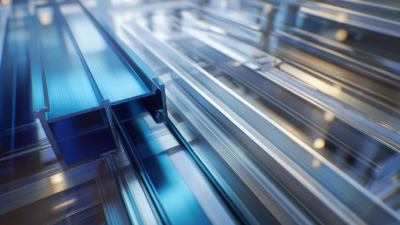

Extruded aluminum profiles have become an integral component in various industries, showcasing their versatility and efficiency. In the automotive sector, they are used to create lightweight structures that enhance fuel efficiency without compromising safety or performance. The strength-to-weight ratio of aluminum makes it ideal for manufacturing components such as chassis, frames, and interior features. This not only reduces the overall weight of vehicles but also supports innovative designs that can improve aerodynamics and contribute to sustainability goals.

In the construction and architecture industries, extruded aluminum profiles play a crucial role in modern building designs. They are often utilized in window frames, curtain walls, and roofing systems, offering exceptional durability and aesthetic appeal. Additionally, these profiles can be easily customized to fit specific design requirements, allowing architects to push the boundaries of creativity. Their resistance to corrosion and low maintenance needs make them a preferred choice in environments exposed to harsh weather conditions, ensuring longevity and structural integrity. As industries continue to innovate, the applications of extruded aluminum profiles are set to expand even further, driving advancements in manufacturing processes.

Extruded aluminum profiles have carved out a significant niche in modern manufacturing, especially when compared to other materials like steel and plastic. One of the key advantages of aluminum is its lightweight nature. This property is particularly important in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance. In contrast, while steel offers strength, its heavier weight can be a drawback when weight savings are a major concern.

Another point of comparison is the adaptability of extruded aluminum. The manufacturing process allows for complex shapes and designs that can be tailored to specific applications, making aluminum highly versatile. In contrast, while plastics can be molded into intricate forms, they may not provide the same level of durability or thermal conductivity that aluminum profiles do. This durability contributes to a longer lifespan of components in various applications, further enhancing the value of aluminum profiles in demanding environments.

This chart illustrates the comparative usage percentage of various materials in modern manufacturing. Extruded aluminum profiles hold a significant share due to their versatility, lightweight nature, and strength, particularly when compared to materials like steel and plastics.

The advancements in extruded aluminum profile technologies signal a vibrant future for the manufacturing sector. With the global demand for lightweight and durable materials rising, innovations such as 3D printing technology and automated extrusion processes are set to revolutionize production capabilities. According to a recent market research report, the aluminum extrusion market is projected to reach $42 billion by 2027, driven by industries such as automotive and aerospace that increasingly rely on high-performance components.

The advancements in extruded aluminum profile technologies signal a vibrant future for the manufacturing sector. With the global demand for lightweight and durable materials rising, innovations such as 3D printing technology and automated extrusion processes are set to revolutionize production capabilities. According to a recent market research report, the aluminum extrusion market is projected to reach $42 billion by 2027, driven by industries such as automotive and aerospace that increasingly rely on high-performance components.

Tip: Manufacturers should consider investing in smart factory technologies that utilize IoT and AI to optimize the extrusion process, enhancing efficiency and reducing waste. Additionally, exploring the integration of sustainable practices, like closed-loop recycling systems, can align with the growing focus on environmental responsibility.

In terms of design innovations, the emergence of complex profile shapes offers engineers the ability to create more efficient and aesthetically appealing products. For instance, thermally broken extrusions are becoming more popular in building applications due to their superior insulation properties. With the increasing focus on energy efficiency and sustainability, these innovations will likely play a pivotal role in the construction industry moving forward.

Tip: Collaboration with suppliers who provide innovative extrusion solutions can lead to faster product development cycles and enhanced design flexibility. Embracing new materials and techniques not only boosts competitiveness but also paves the way for groundbreaking applications in diverse sectors.