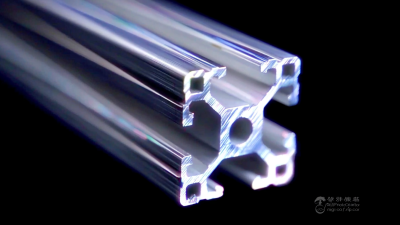

In the competitive landscape of manufacturing, optimizing production processes is key to enhancing efficiency and maintaining profitability. This is especially true in the realm of Aluminum Extrusion Profiles, where precision and speed are paramount. Effective strategies not only elevate output but also improve product quality and reduce operational costs. In this blog, we will explore seven essential tips designed to maximize efficiency in the production of Aluminum Extrusion Profiles. From advanced technology integration to streamlined workflows, these insights will empower manufacturers to navigate challenges and harness opportunities in an evolving market. Join us as we delve into best practices that can transform your production line into a model of efficiency and productivity.

In the aluminum extrusion industry, maximizing production efficiency is crucial for maintaining competitiveness and profitability. According to a report by the Aluminum Association, enhancing the efficiency of extrusion processes can lead to a reduction in production costs by up to 30%. A key factor in this optimization is the careful selection and management of material properties. Utilizing high-quality alloys can significantly influence extrusion speed and finish quality, which are imperative for meeting client specifications.

In the aluminum extrusion industry, maximizing production efficiency is crucial for maintaining competitiveness and profitability. According to a report by the Aluminum Association, enhancing the efficiency of extrusion processes can lead to a reduction in production costs by up to 30%. A key factor in this optimization is the careful selection and management of material properties. Utilizing high-quality alloys can significantly influence extrusion speed and finish quality, which are imperative for meeting client specifications.

Another pivotal factor is the operational parameters involved in the extrusion process itself. A study by the International Journal of Advanced Manufacturing Technology highlights that fine-tuning variables such as extrusion temperature and die design can accelerate production rates. For instance, implementing proper heat treatment processes before extrusion can enhance material flow and minimize defects, resulting in a lower rejection rate of extruded profiles. By focusing on these key factors, manufacturers can not only improve their operational efficiency but also deliver superior products to market, ultimately driving growth in the aluminum sector.

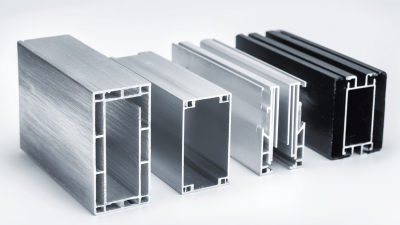

In the competitive landscape of aluminum extrusion profiles production, implementing advanced technology can drastically enhance efficiency and output quality. Recent industry reports indicate that companies employing automated systems and real-time monitoring can increase production rates by up to 30%. Innovations such as artificial intelligence and machine learning optimize the extrusion process by predicting defects and streamlining workflows, ultimately leading to reduced waste and energy consumption.

One vital tip for maximizing efficiency is the integration of advanced robotics in handling materials. Robotic systems can not only speed up the loading and unloading of profiles but also reduce the risk of workplace injuries, thereby enhancing overall operational productivity. Additionally, utilizing data analytics tools allows manufacturers to track performance in real-time, enabling quick adjustments that can improve yield and decrease downtime.

Another essential consideration is adopting energy-efficient technologies in production machinery. According to a recent study by the Aluminum Association, implementing energy-saving technologies can reduce electricity consumption in extrusion processes by 15-25%. This not only cuts operational costs but also supports sustainability goals, making it an attractive option for modern aluminum extrusion manufacturers seeking to enhance their processes.

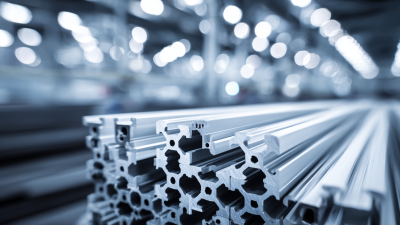

Streamlining workflow in aluminum extrusion profiles production is essential for maintaining competitive advantages in the industry. Research indicates that operational efficiency can be improved by up to 30% through the implementation of effective workflow strategies. This improvement not only enhances productivity but also reduces lead times, which is crucial in meeting customer demands in a fast-paced market.

One effective tip to maximize efficiency is adopting lean manufacturing principles. This approach minimizes waste and optimizes processes by focusing on value-added activities. For instance, a recent industry report from the Aluminum Association revealed that companies applying lean techniques have seen a reduction in production cycle times by approximately 25%. Another important strategy is automating repetitive tasks, which not only accelerates production but also reduces human error, leading to higher quality standards.

Additionally, investing in employee training and development plays a key role in streamlining workflow. A skilled workforce can identify inefficiencies and suggest improvements that can lead to significant cost savings. Implementing regular training programs can enhance technical skills and foster a culture of continuous improvement, ultimately contributing to the overall efficiency of aluminum extrusion profiles production.

| Tip # | Strategy | Expected Outcome | Implementation Timeframe |

|---|---|---|---|

| 1 | Optimize Material Usage | Reduced Waste | 1-2 Weeks |

| 2 | Implement Lean Manufacturing | Increased Efficiency | 3-4 Weeks |

| 3 | Enhance Employee Training | Improved Skill Levels | Ongoing |

| 4 | Utilize Automation | Faster Production Times | 6-12 Months |

| 5 | Streamline Supply Chain | Reduced Lead Times | 2-3 Months |

| 6 | Conduct Regular Maintenance | Minimized Downtime | Ongoing |

| 7 | Solicit Customer Feedback | Enhanced Product Quality | Continuous |

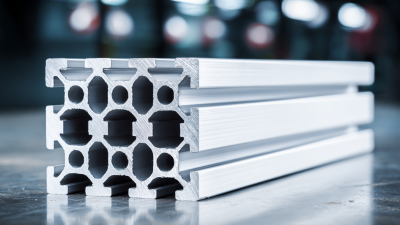

Maximizing resource utilization in aluminum profile production is crucial for enhancing efficiency and reducing costs. According to a report by the Aluminum Association, optimizing material usage can cut production waste by up to 20%, translating to significant savings over time. Effective resource management not only lowers raw material expenses but also minimizes environmental impact, aligning with the industry's shift towards sustainability.

One key strategy is adopting advanced technology such as automated cutting and machining systems. These innovations help reduce scrap rates and can increase production capacity by 30%, as highlighted in a study from the International Aluminum Institute. Additionally, implementing a stringent quality control process can ensure that each extrusion profile meets specifications, reducing rework and further conserving resources. By focusing on these efficient practices, manufacturers can enhance productivity while promoting sustainable practices in aluminum extrusion.

In the competitive landscape of aluminum extrusion profiles production, the focus on training and development cannot be overstated. By investing in your team’s skills, you empower them to work more efficiently, minimizing errors and waste throughout the production process. This commitment to professional growth fosters a culture of continuous improvement, where employees are more engaged and motivated to contribute innovative solutions. Implementing regular training sessions and workshops not only enhances their technical abilities but also keeps them updated on the latest industry trends and technologies.

Moreover, nurturing a well-trained workforce leads to better collaboration and communication among team members. As they become more adept at their roles, they can share insights and feedback, resulting in a streamlined production process. Facilitating mentorship initiatives can pair less experienced employees with seasoned professionals, creating a strong support system and knowledge transfer that maximizes operational efficiency. Ultimately, investing in training and development is not just about enhancing individual performance; it's about cultivating a resilient team capable of driving the company toward greater success in the aluminum extrusion profiles market.

This bar chart illustrates the key factors affecting efficiency in aluminum extrusion profiles production.