When embarking on a project that requires the use of Aluminum Channel Extrusion Profiles, selecting the right profile can significantly impact both functionality and aesthetic appeal. According to a recent industry report by Freedonia Group, the demand for aluminum extrusions is projected to reach $8 billion by 2025, reflecting a growing reliance on these versatile materials in various sectors, including construction, automotive, and consumer goods. The unique properties of aluminum, such as its lightweight nature, corrosion resistance, and recyclability, make it an ideal choice for engineers and designers. However, with a plethora of options available, understanding the specific requirements of your project—such as load capacity, thermal conductance, and surface treatment—is crucial. This guide aims to provide key insights into how to effectively choose Aluminum Channel Extrusion Profiles that will not only meet your technical specifications but also enhance the overall success of your design.

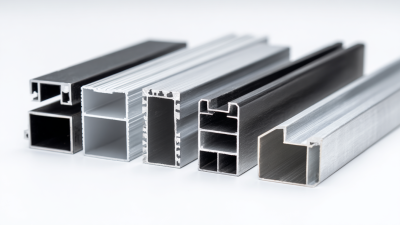

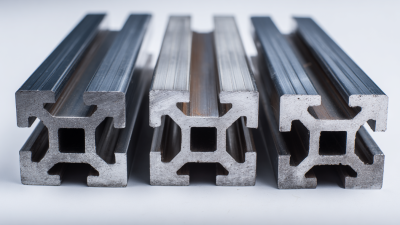

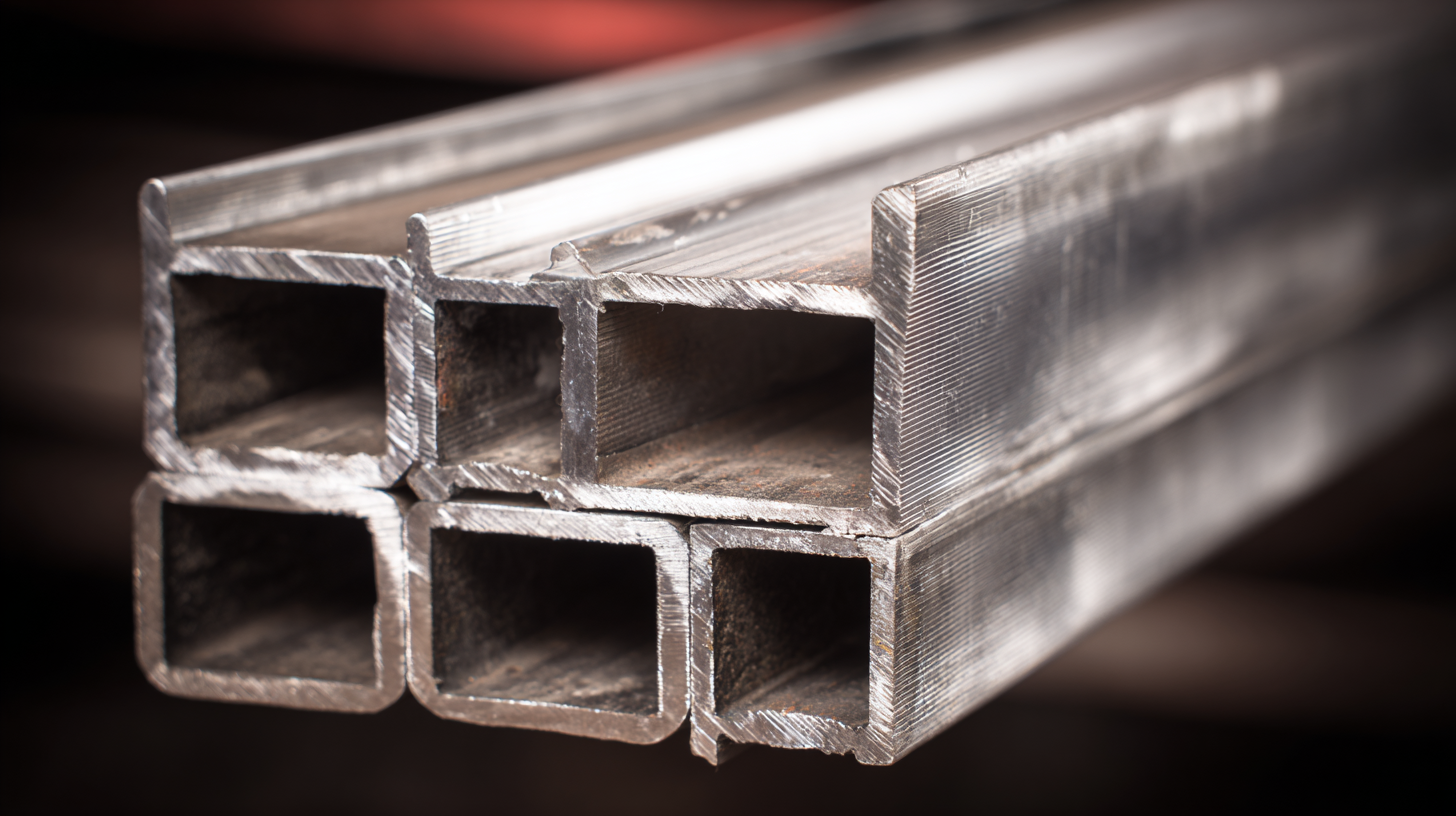

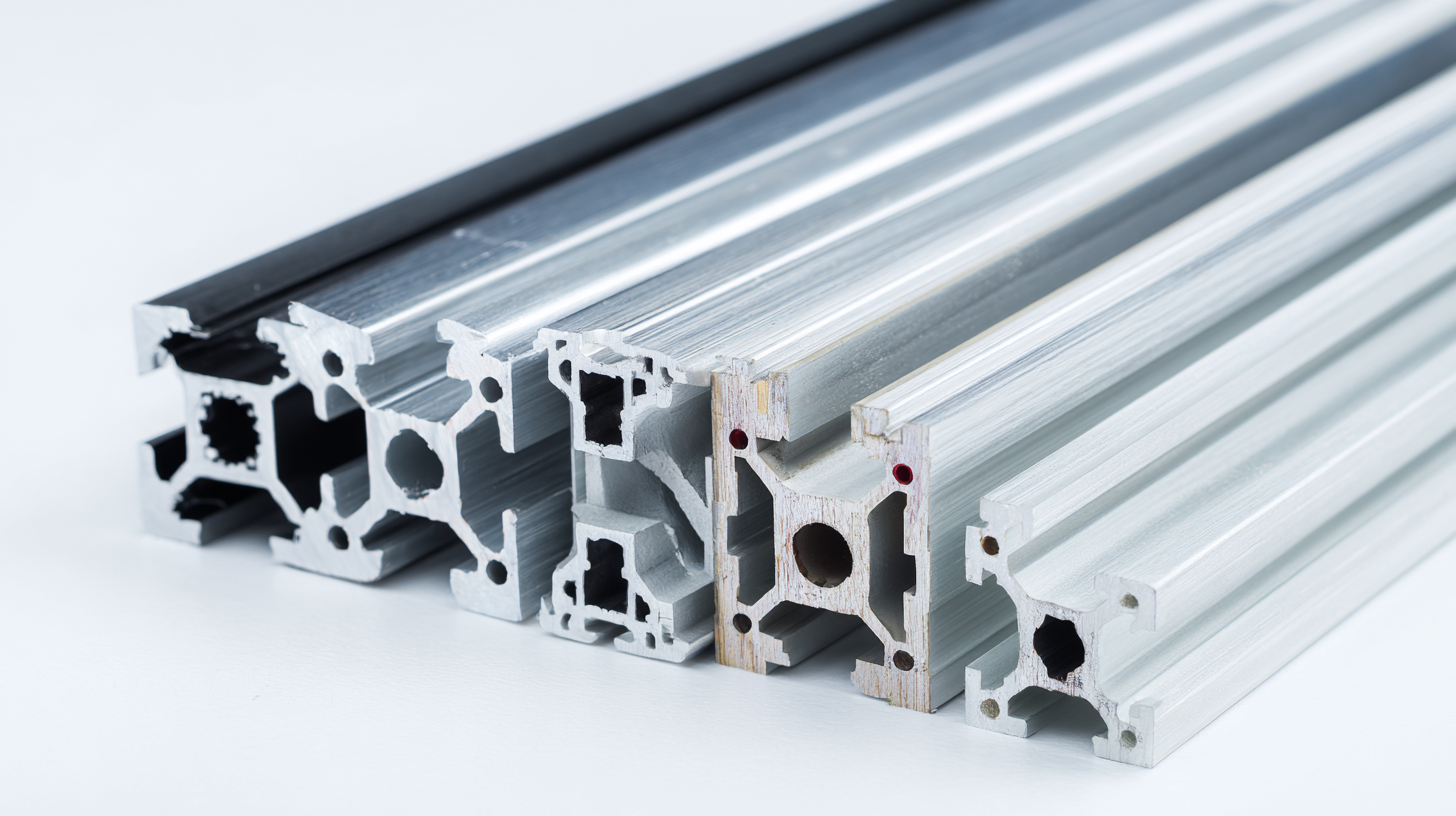

When selecting aluminum channel extrusion profiles for specific projects, it is essential to understand the various types available in the market. Aluminum channel extrusions come in numerous shapes and sizes, each designed for particular applications, ranging from structural support to aesthetic finishes. Common profiles include L-shaped, U-shaped, and rectangular channels, each offering distinct benefits depending on the intended use, such as load-bearing capabilities or ease of assembly.

Moreover, selecting the right aluminum channel profile hinges on factors such as material properties and environmental considerations. For instance, in automotive manufacturing, aluminum is often preferred for its lighter weight and resistance to corrosion compared to steel. This shift towards aluminum is driving market growth, with the aluminum extrusion market projected to reach USD 217.3 billion by 2035, reflecting a compound annual growth rate (CAGR) of 4.6% from 2025 to 2035. Understanding these diverse options will enable better decision-making, ensuring that the aluminum channel profile chosen meets the functional and aesthetic demands of the project.

When selecting aluminum channel extrusion profiles for your project, there are several key factors to consider. First, it's crucial to assess the specific application of the aluminum channels. Different projects may require different characteristics, such as load-bearing capacity, corrosion resistance, or aesthetic appeal. Make sure to identify the load requirements and environmental conditions the profiles will face, as these will significantly influence the selection process.

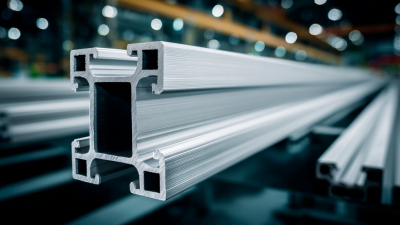

Another important factor is the alloy and temper of the aluminum used in the extrusion. Different alloys have varying strengths, weights, and resistance to degradation. Understanding these properties will help you choose the right profile that meets your durability and performance needs. Additionally, the manufacturing process and quality assurance standards of the supplier can significantly impact the final product. Ensuring that the supplier adheres to high manufacturing standards will contribute to the overall performance and lifespan of the extrusion profiles.

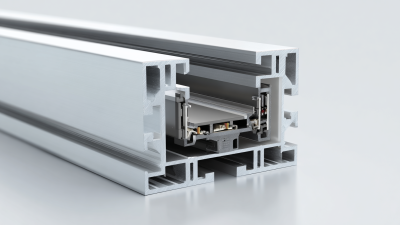

When selecting aluminum channel extrusions for a project, understanding their load-bearing capacities is crucial. Aluminum channels are commonly used in various structural applications due to their lightweight properties and resistance to corrosion. However, not all profiles are created equal. The load-bearing capacity of an aluminum channel is influenced by its dimensions, wall thickness, and alloy composition. For instance, a wider or thicker channel can typically support heavier loads, making it essential to align the extrusion specifications with the demands of your specific application.

To accurately assess the load-bearing capabilities of an aluminum channel extrusion, engineers often refer to standardized loading calculations. These include factors such as bending, shear, and deflection limits, which provide insights into how much weight the channel can sustain without structural failure. Additionally, it's essential to consider the orientation of the channel during installation, as this can affect its performance under load. By analyzing these variables, project managers can select the right aluminum channel profiles that not only meet safety standards but also enhance the overall structural integrity of their projects.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Effective Load Capacity (kg) | Typical Applications |

|---|---|---|---|---|

| C-Channel | 30 x 15 | 1.50 | 150 | Structural support, framing |

| U-Channel | 40 x 20 | 1.80 | 200 | Decking, wall support |

| L-Channel | 50 x 50 x 5 | 2.20 | 300 | Brackets, shelving |

| T-Channel | 40 x 40 | 1.50 | 250 | Framework, machinery |

| Flat Bar | 25 x 5 | 0.90 | 100 | Supports, reinforcements |

When selecting aluminum channel extrusion profiles for your project, understanding the comparative costs of different options and their lifecycle value is crucial. According to a report by the Aluminum Association, the average cost of aluminum extrusions ranges from $3.00 to $5.00 per pound, depending on the alloy and complexity of the profile. More intricate profiles tend to incur higher costs due to the additional processing involved, making it essential to evaluate how these costs align with your project's budget and performance requirements.

Moreover, a lifecycle analysis conducted by the International Aluminium Institute emphasizes the long-term value of investing in high-quality aluminum extrusions. While the upfront costs may be higher, choosing profiles designed for durability and efficiency can lead to significant savings over time. Projects utilizing premium aluminum profiles can see reduced maintenance costs and extended service life, with many extrusions lasting 30 years or more in service. This durable performance ultimately translates to lower total lifecycle costs, stressing the importance of considering not just initial expense but also the long-term economic impact of your chosen materials.

When selecting aluminum channel extrusion profiles for your project, understanding the relevant industry standards and certifications is crucial. These standards ensure that the products you choose meet specific performance criteria and quality benchmarks. Key organizations, such as the American Society for Testing and Materials (ASTM) and the Aluminum Association, provide guidelines that help manufacturers create profiles that are consistent in their mechanical properties and durability. Familiarity with these standards will not only enhance the reliability of your project but also ensure compliance with regulations that may pertain to safety and environmental impact.

In addition to industry standards, certifications play a significant role in the selection process. Look for profiles that have certifications like ISO 9001 or the Lean Manufacturing Certification, which indicate adherence to quality management principles and best practices. These certifications guarantee that the manufacturer implements rigorous quality control throughout the production process, offering you peace of mind regarding the material's integrity. By prioritizing profiles that meet recognized standards and hold relevant certifications, you can make informed decisions that align with your project’s requirements and contribute to its long-term success.