Aluminum Frame Extrusion Profiles play a critical role in various industries, from construction to electronics. According to a recent market report, the global aluminum extrusion market is projected to reach USD 127 billion by 2027. This growth emphasizes the importance of selecting the right profiles for specific applications.

In designing with aluminum extrusion, engineers often overlook the potential of optimized profiles. Poor choices can lead to structural weaknesses and increased costs. The right aluminum frame extrusion profiles enhance durability and efficiency. On the other hand, a lack of understanding might result in wasted materials and time.

As you consider your next project, think about how different profiles can meet unique requirements. Based on industry analysis, lightweight yet robust designs are preferred. This focus on quality and functionality ensures longevity. It’s essential to acknowledge that not every profile fits every project, prompting critical evaluation.

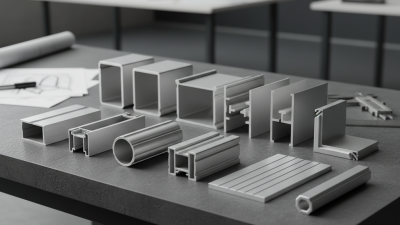

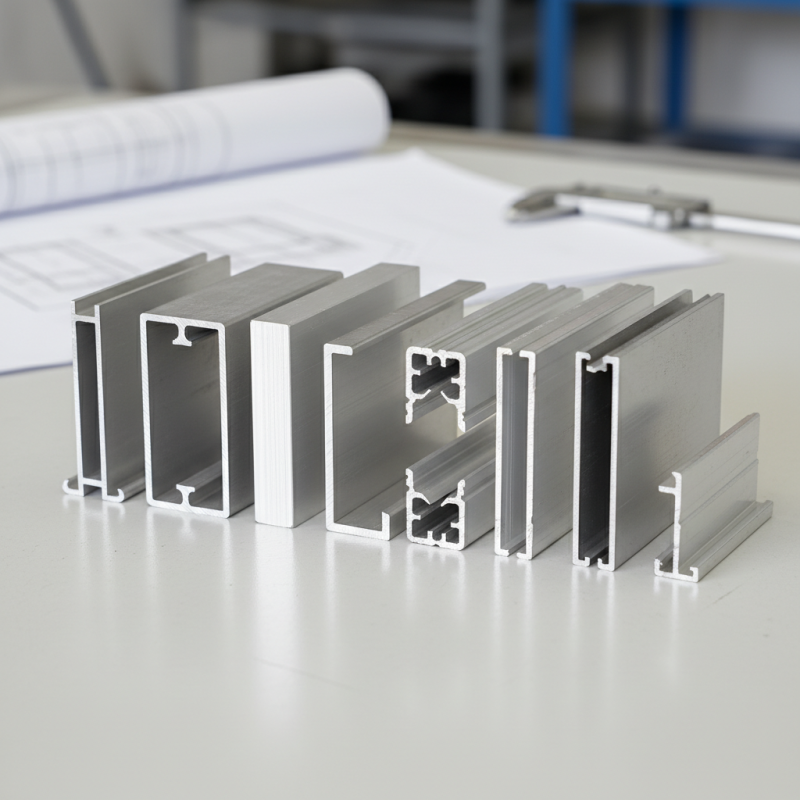

Aluminum frame extrusion is a technique used in various applications. It involves shaping aluminum by forcing it through a mold. This process creates profiles that are versatile and durable. The resulting frames are lightweight yet strong, making them ideal for many construction projects.

One major advantage of aluminum extrusion is its adaptability. Designers can create custom profiles to fit specific needs. Whether for windows, doors, or furniture, these frames can be tailored to unique specifications. However, achieving the perfect design can be challenging. Sometimes, the initial prototypes may not meet expectations. Iterating on designs is often necessary, and this can lead to delays.

Lastly, the environment also plays a role. Aluminum can withstand various weather conditions, yet it can corrode over time. Regular maintenance is important to ensure longevity. Selecting the right finish can mitigate these issues, but it requires careful consideration. Understanding the properties of aluminum frame extrusion is essential for any successful project.

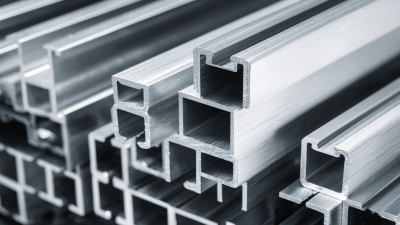

Aluminum frame extrusions are gaining popularity in various industries. They offer several key advantages that make them an ideal choice for many projects. According to a 2022 report from the Aluminum Association, aluminum's particular strength-to-weight ratio is superior to other materials. This makes aluminum frames easier to handle and install, streamlining the construction process.

The durability of aluminum is another distinct benefit. Unlike wood or plastic, aluminum is resistant to corrosion and degradation. A research study indicated that aluminum can last over 50 years in harsh environments. This longevity translates into lower maintenance costs and reduced environmental impact. However, it's essential to consider the upfront costs. Depending on the complexity of the fabrication, initial expenses can be higher than traditional materials.

Additionally, aluminum is highly recyclable, contributing to a sustainable approach in construction. The International Aluminum Institute reported that 75% of all aluminum produced is still in use today. Yet, not all aluminum products are created equal. Variances in quality can affect overall performance in real-world applications. Every project demands careful consideration of material choices and quality standards.

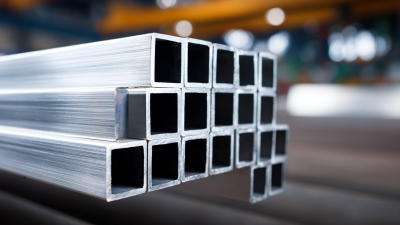

| Profile Type | Dimensions (mm) | Weight (kg/m) | Applications | Advantages |

|---|---|---|---|---|

| Square Tube | 25 x 25 | 1.5 | Frameworks, Furniture | High strength, Cost-effective |

| Rectangular Tube | 40 x 20 | 2.3 | Industrial Racks | Versatile, Easy to assemble |

| L-Shaped Angle | 30 x 30 | 1.0 | Bracing, Supports | Strong, Lightweight |

| T-Slot Profile | 40 x 40 | 1.8 | Machine Frames, Guards | Flexible design, Easily customizable |

| I-Beam | 50 x 100 | 3.5 | Heavy-duty applications | High load capacity, Stability |

| Round Profile | 25 | 0.8 | Frameworks, Articulating parts | Corrosion resistance, Aesthetically pleasing |

| C-Channel | 50 x 25 | 2.0 | Shelving, Support beams | Strong, Cost-effective |

| Hollow Tube | 30 x 30 | 1.2 | Frames, Light structures | Lightweight, Easy handling |

| Z-Section | 60 x 40 | 2.5 | Structural applications | High strength, Efficient use of materials |

| Angle Profile | 50 x 50 | 1.7 | Framing and Joining | Robustness, Easy assembly |

Aluminum frame extrusion profiles are versatile and popular in various applications. They are lightweight yet strong, making them ideal for structural designs. Many builders use these profiles in construction projects, from residential homes to commercial buildings. Their adaptability allows for unique designs, but planning is crucial. A poorly designed frame can lead to instability.

In automotive manufacturing, aluminum profiles play a critical role. They are used in vehicle frameworks and parts to enhance fuel efficiency. The lightweight nature of aluminum reduces overall weight, but precision is necessary. An improper fit can cause issues in both safety and performance. In industrial applications, these profiles are essential for creating custom workstations and assembly lines. They enable quick adjustments and expansions, but sometimes the solutions may not be perfect.

Moreover, aluminum frame profiles find their way into furniture design. Modern pieces often incorporate these sleek, elegant frames. While they look appealing, ensuring comfort and functionality is challenging. Designers must balance aesthetics with practical use. Therefore, careful consideration is needed in every project.

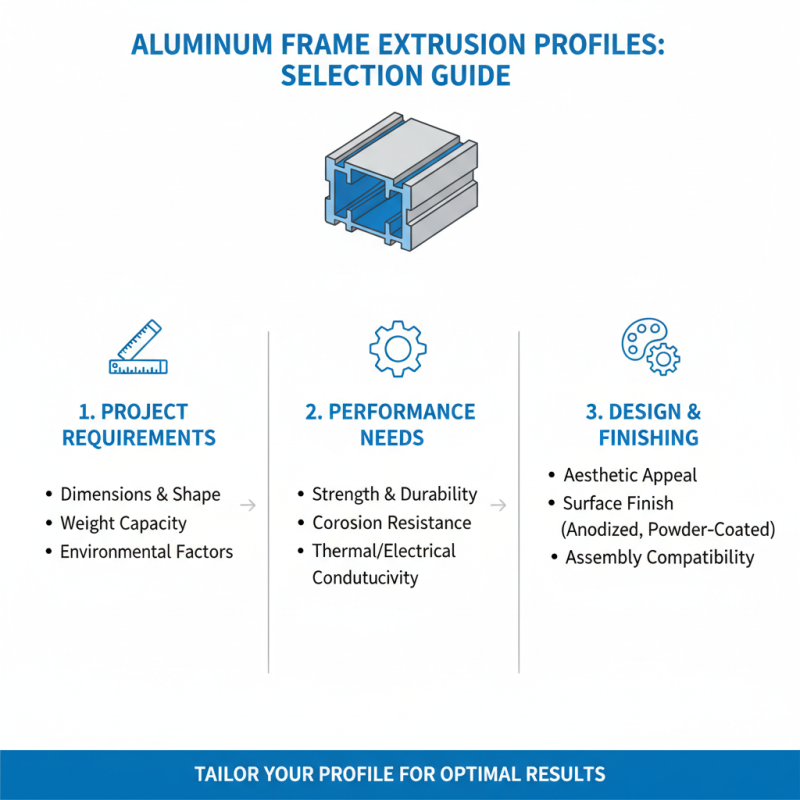

When selecting aluminum frame extrusion profiles, careful consideration is vital. Start by assessing the specific requirements of your project. Think about the dimensions, weight capacity, and the desired aesthetic. Each project has unique needs, so tailoring your profile to fit these requirements is crucial.

Tips: Look for profiles with varying wall thicknesses. Thicker walls can enhance strength, while thinner walls may reduce weight. Flexibility in design offers better adaptability.

Another important factor is the intended application. Different environments demand specific properties. For example, profiles used in outdoor settings must resist corrosion. Consider how your finished product will withstand environmental stressors over time.

Tips: Consult with professionals to choose the best alloys. Some may provide better durability while others excel in workability.

Stay mindful of the available manufacturing processes. Techniques like CNC machining or welding might affect the final product quality. Be open to modifications but ensure they align with your overall vision. Reflect on potential challenges, as flexibility can be both a strength and a limitation in project execution.

Aluminum extrusions are becoming essential in various industries. The latest designs focus on versatility and efficiency. According to a recent industry report, the global aluminum extrusion market is expected to reach $150 billion by 2027. This growth is driven by innovative ideas in product development.