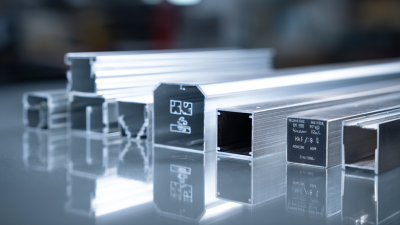

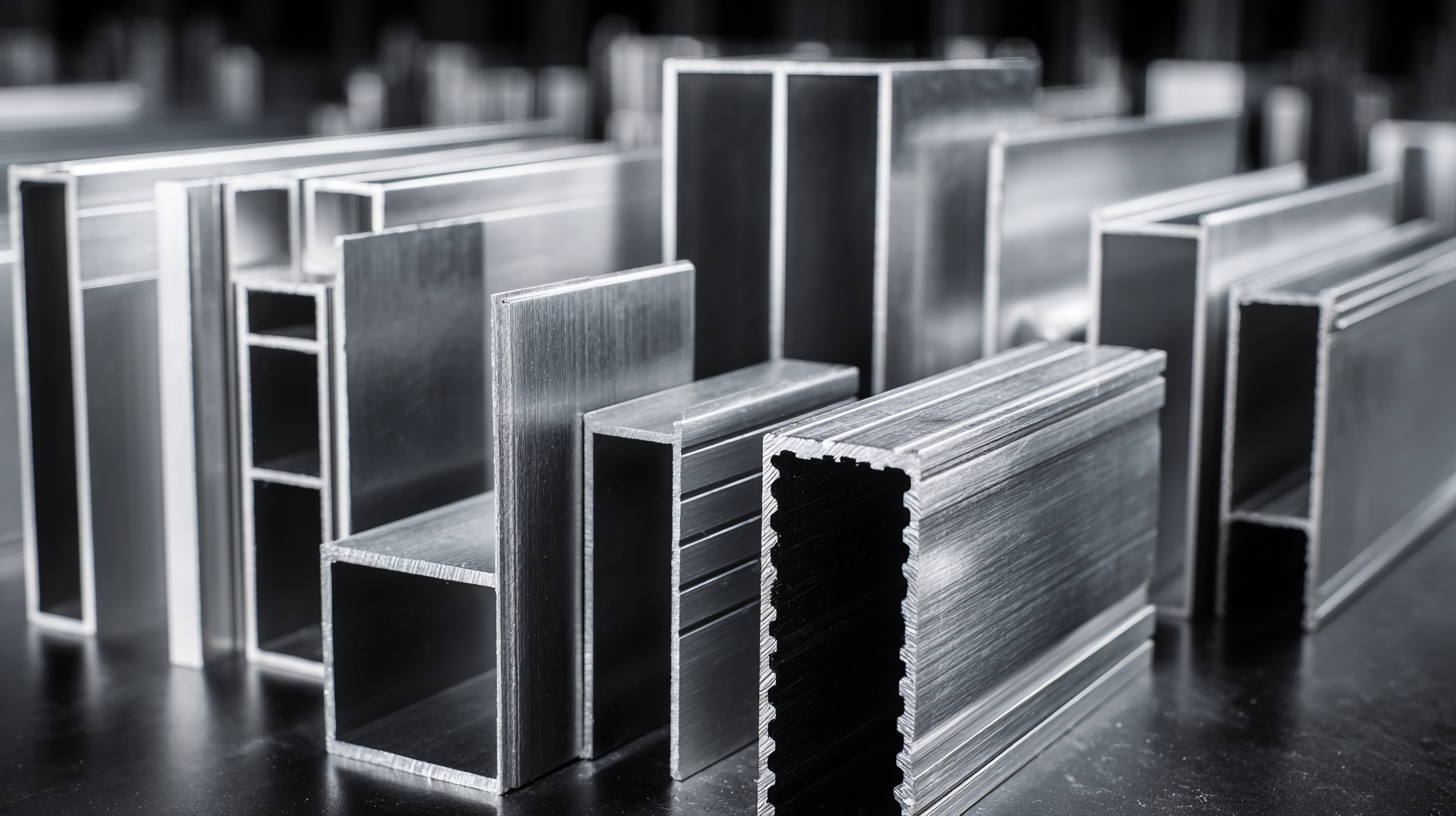

In the ever-evolving landscape of design and architecture, Aluminum Moulding Profiles have emerged as a crucial element that combines functionality with aesthetic appeal. According to a recent industry report by MarketsandMarkets, the global aluminum extrusion market is projected to reach USD 219 billion by 2026, growing at a CAGR of 5.8%. This trend underscores the growing recognition of aluminum's versatility in various applications, from residential to commercial spaces. The lightweight yet durable nature of Aluminum Moulding Profiles not only enhances structural integrity but also allows for innovative design possibilities, making them a preferred choice for architects and designers worldwide. As the industry continues to embrace sustainability and efficiency, these profiles are set to play a pivotal role in shaping the future of modern architecture, offering solutions that meet both aesthetic desires and practical requirements.

Aluminum moulding profiles have undergone significant evolution in modern design, driven by their versatility and aesthetic appeal. In recent years, the demand for lightweight, durable materials has surged, particularly in the architecture and construction industries. According to industry reports, the global aluminum profiles market is projected to grow at a CAGR of 4.1% from 2020 to 2027, highlighting the increasing preference for aluminum due to its strength-to-weight ratio and resistance to corrosion.

The integration of aluminum moulding profiles into contemporary architectural projects has enabled designers to push the boundaries of creativity. The sleek lines and finish offered by aluminum not only enhance the visual appeal of structures but also contribute to energy efficiency. A report by the Aluminum Association indicates that using aluminum can lead to a 30% reduction in energy consumption in building applications. As architects and designers continue to explore innovative ways to incorporate aluminum profiles, the material's role is poised to expand, reaffirming its status as a staple in modern design and architecture.

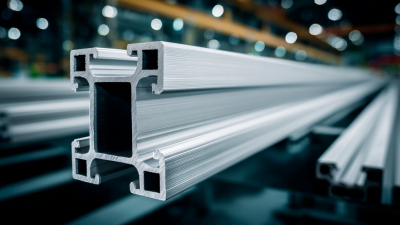

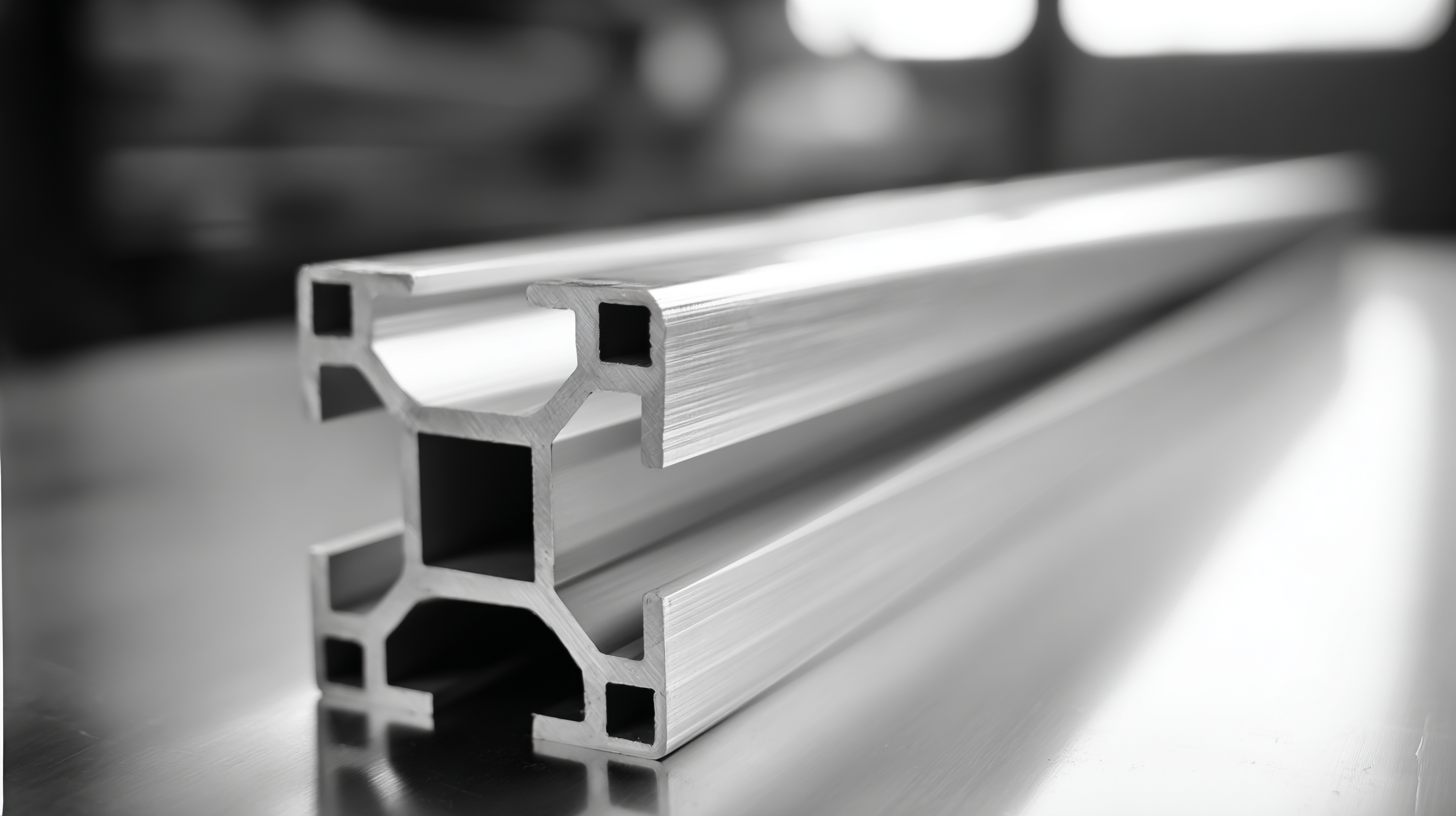

Aluminum moulding profiles are rapidly becoming a cornerstone in modern architecture due to their adaptability and functional benefits. Their lightweight yet durable nature allows architects and designers to explore innovative design solutions without compromising structural integrity. The use of aluminum moulding in architectural applications enhances energy efficiency while promoting sustainability, as its properties allow for better insulation and consequently lower energy consumption.

Tips: When considering aluminum moulding, always take into account the specific design requirements of your project. Ensure that the profiles chosen not only fulfill aesthetic criteria but also enhance the functional aspects of the building. Research customizable options that can cater to unique design needs.

Furthermore, advancements in manufacturing techniques, such as rapid casting, have led to the development of specialized structures like ordered porous aluminum. These innovations highlight the material's superior compressive properties and energy absorption behavior, making it an excellent choice for various architectural applications. By leveraging these characteristics, designers can create structures that are not only visually appealing but also resilient and safe.

Tips: Always assess the manufacturing techniques available for aluminum moulding. Consider how the choice of production methods can influence the final properties of the profiles, as this will contribute significantly to the overall performance of your designs.

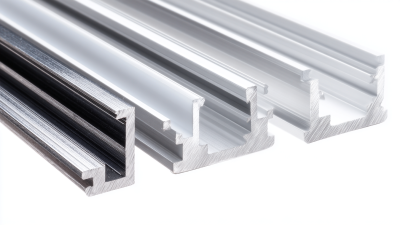

Aluminum moulding profiles are redefining the landscape of interior design, offering an exciting mix of aesthetics and functionality. As the architectural world embraces innovation, these profiles have become a versatile choice for interior spaces, seamlessly blending with various design themes. The lightweight nature of aluminum allows for complex shapes and elegant finishes that enhance both the visual appeal and structural integrity of spaces.

In the fast-paced fenestration industry, aluminum's role has become increasingly significant. It not only allows for the creation of expansive windows and facades but also provides energy-efficient solutions that meet modern sustainability demands. The integration of aluminum profiles into interior decor—ranging from sleek window frames to decorative elements—offers architects and designers greater flexibility to craft unique environments that cater to both form and function. As this trend continues to evolve, we can expect to see more innovative applications that push the boundaries of traditional design.

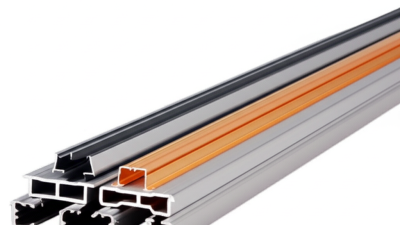

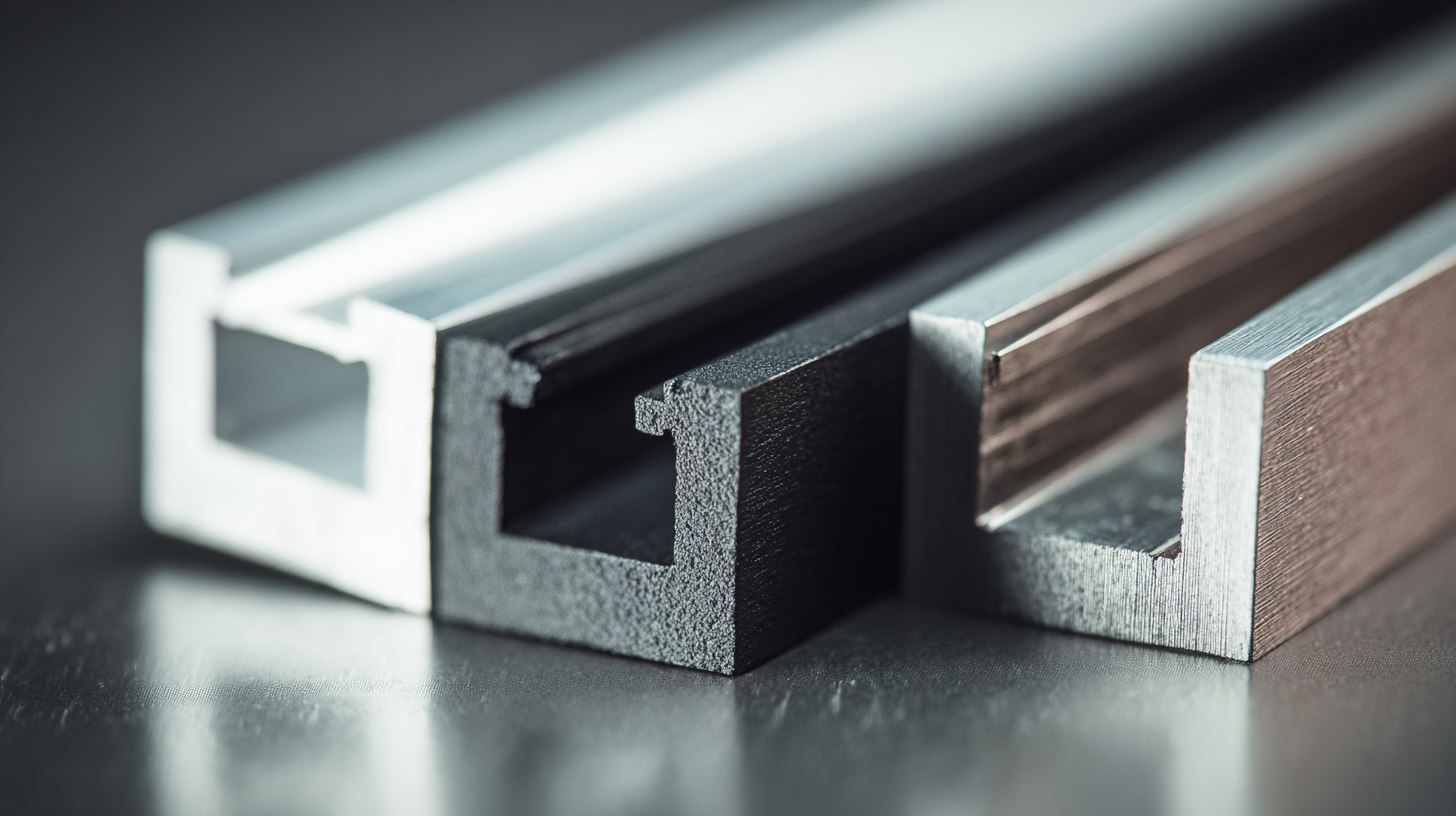

Aluminum moulding profiles are increasingly recognized for their sustainability and recyclability, making them pivotal in modern design and architecture. As the global aluminum market continues to grow, with a reported size of over $150 billion in North America alone, the shift towards eco-friendly materials is more pronounced than ever. The extrusion processes used in creating aluminum profiles not only allow for intricate design possibilities but also contribute to their longevity and ability to be reused, reinforcing the material's standing in sustainable construction practices.

The recyclability of aluminum is a significant advantage, with approximately 75% of all aluminum ever produced still in use today. This highlights the potential for minimized waste in architectural applications, supporting a circular economy. Furthermore, products such as aluminum sheets and extrusions are not only lightweight and durable but also energy-efficient to produce, leading to lower carbon footprints compared to alternative materials. As architects and designers increasingly lean towards sustainable solutions, aluminum moulding profiles offer a robust choice that aligns with both environmental goals and innovative design trends.

Aluminum moulding profiles are rapidly emerging as a game-changer in design and architecture, driven by their remarkable versatility and adaptability. According to a recent report by MarketsandMarkets, the global aluminum extrusion market is projected to reach USD 150 billion by 2025, fueled by the increasing demand for lightweight, high-strength materials in various construction applications. This growing trend signifies a shift towards sustainable building solutions that leverage aluminum's recyclability and durability. Designers and architects are now incorporating aluminum profiles not just for structural support but also for aesthetic and functional enhancements, leading to innovative building designs that meet modern needs.

Furthermore, the integration of aluminum moulding profiles in architectural projects aligns with the principles of sustainable design. According to the Aluminum Association, using aluminum in construction can lead to a reduction in energy consumption by up to 30% due to its thermal efficiency properties. The trend is also reflected in recent projects where aluminum profiles are being used creatively to create sleek and contemporary facades, enhance natural lighting, and improve overall energy performance. As the architectural landscape evolves, the future of design looks promising with aluminum moulding profiles at the forefront, demonstrating that functionality can seamlessly blend with innovative aesthetics.